Interfaces

Interfaces

Module List I

Module List I

CA1 2D DXF and IGES Export

Rights: K05a, K05e

CB1 STEP and Parasolid format export in 3D

using the Parasolid kernel

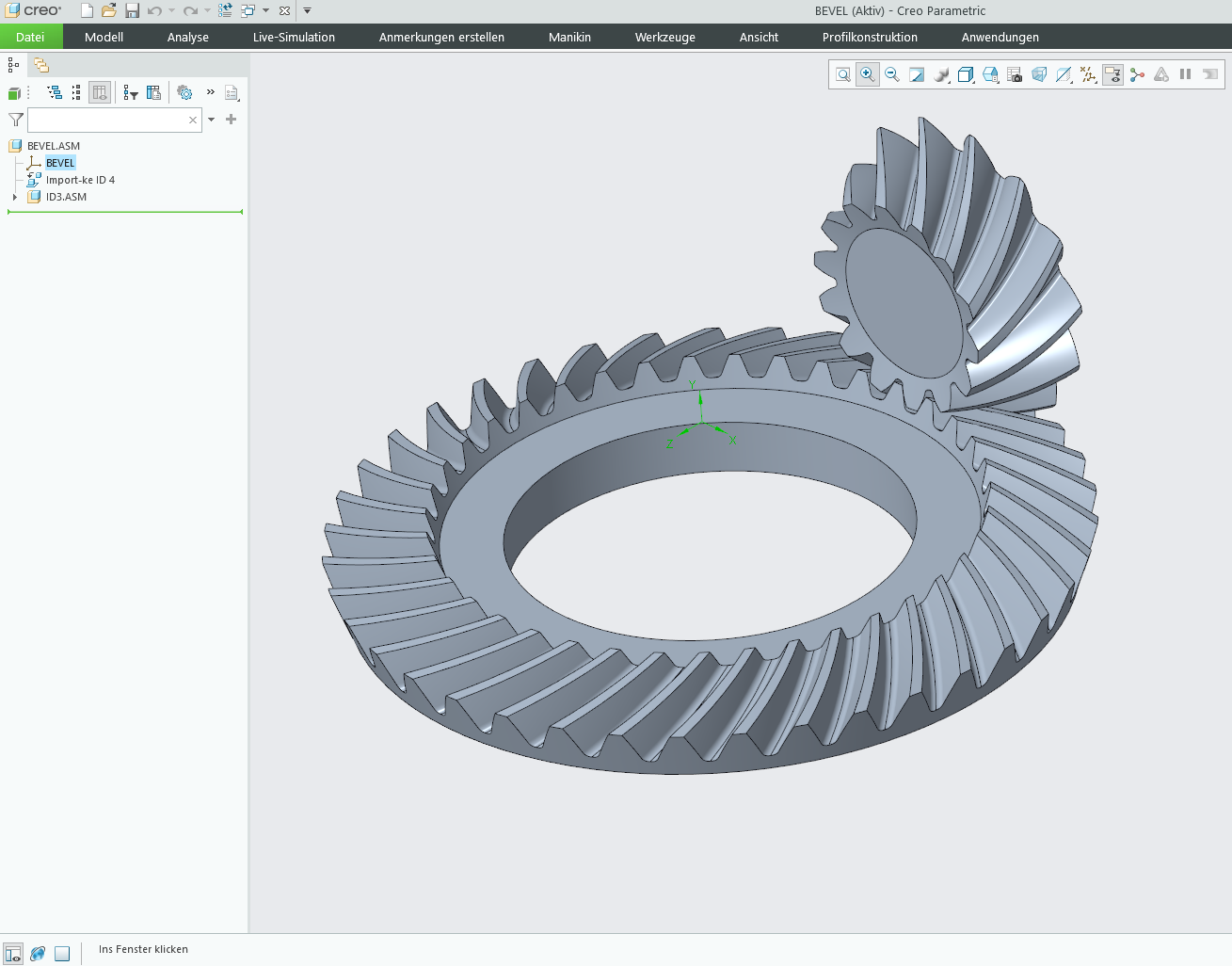

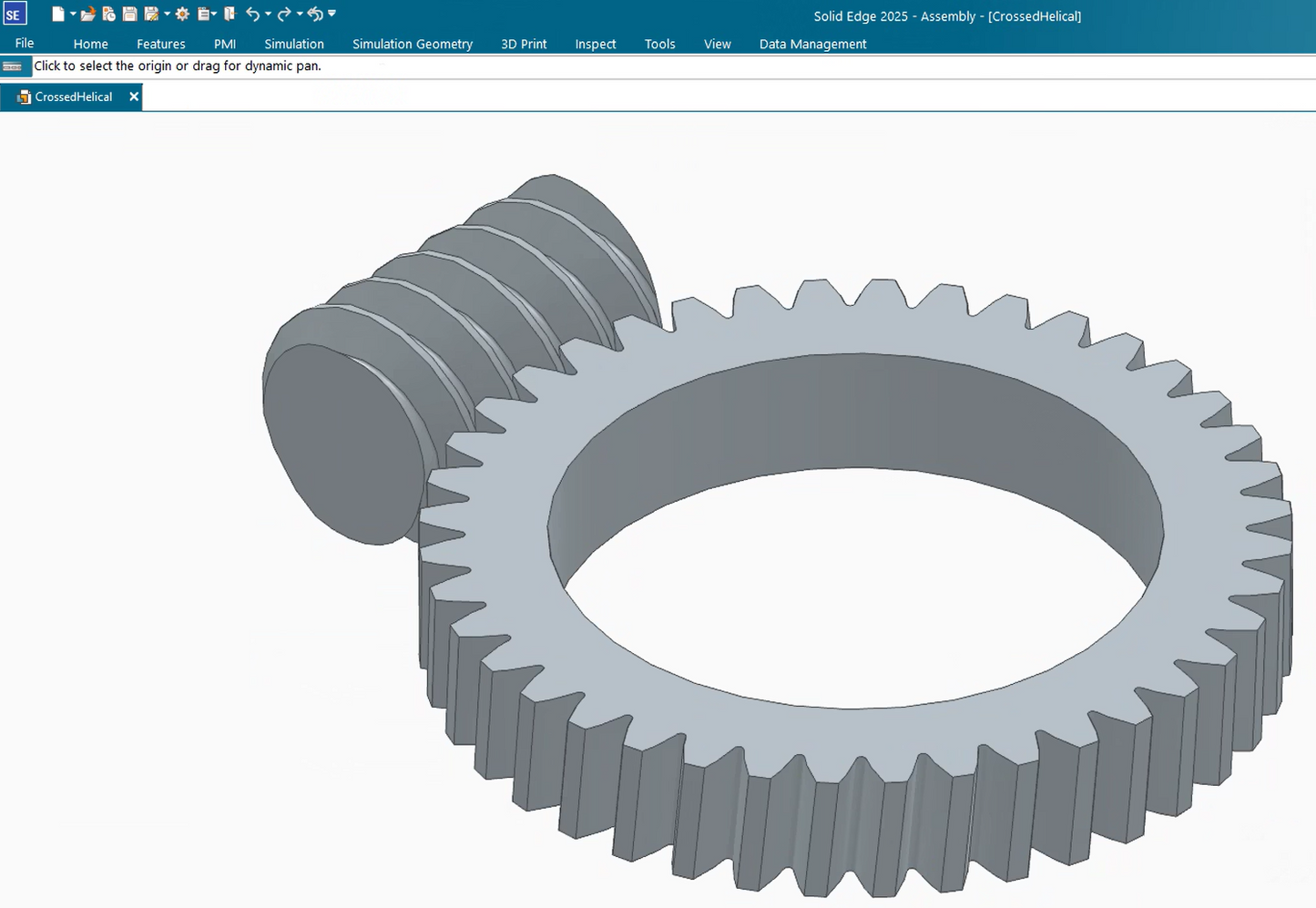

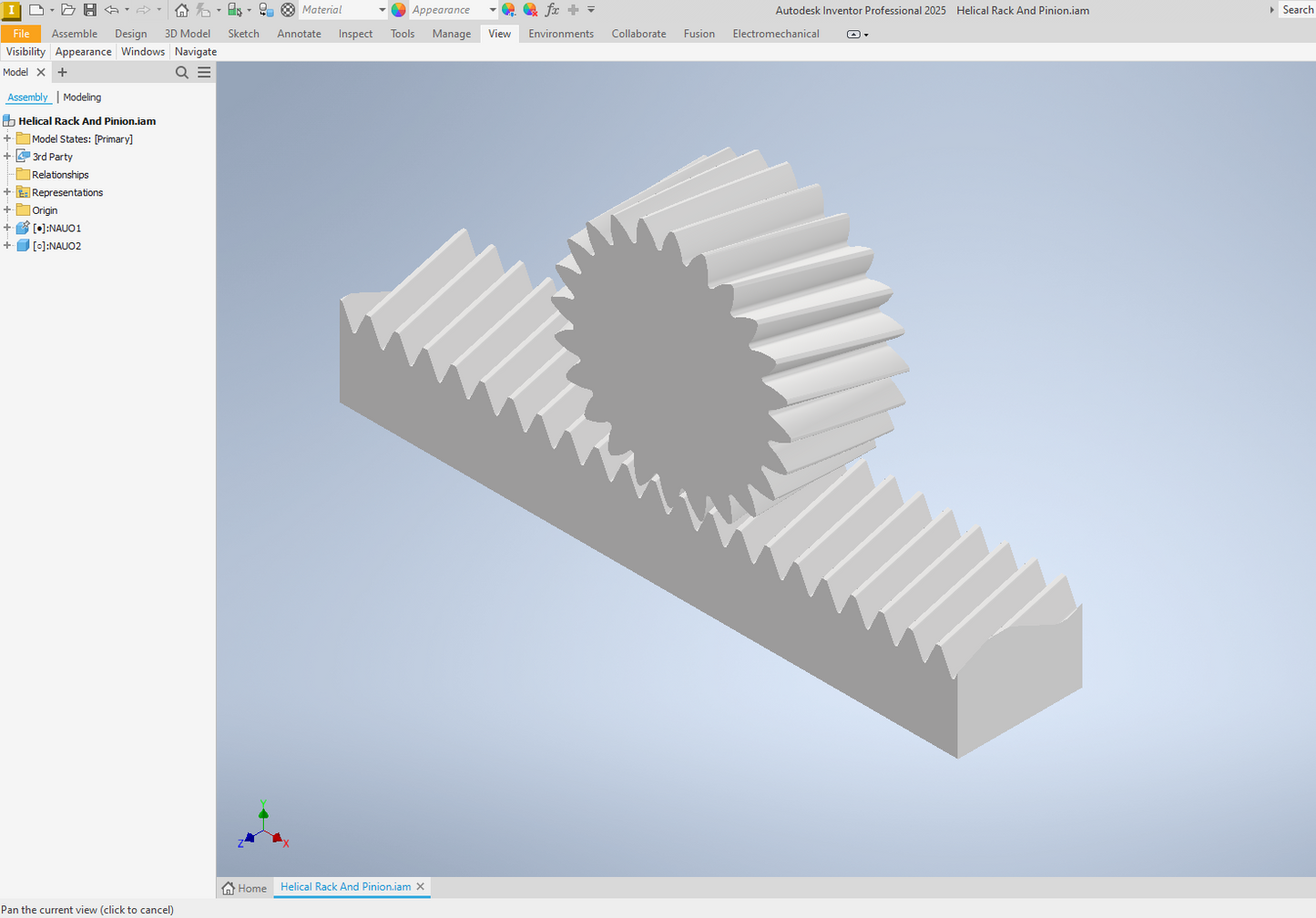

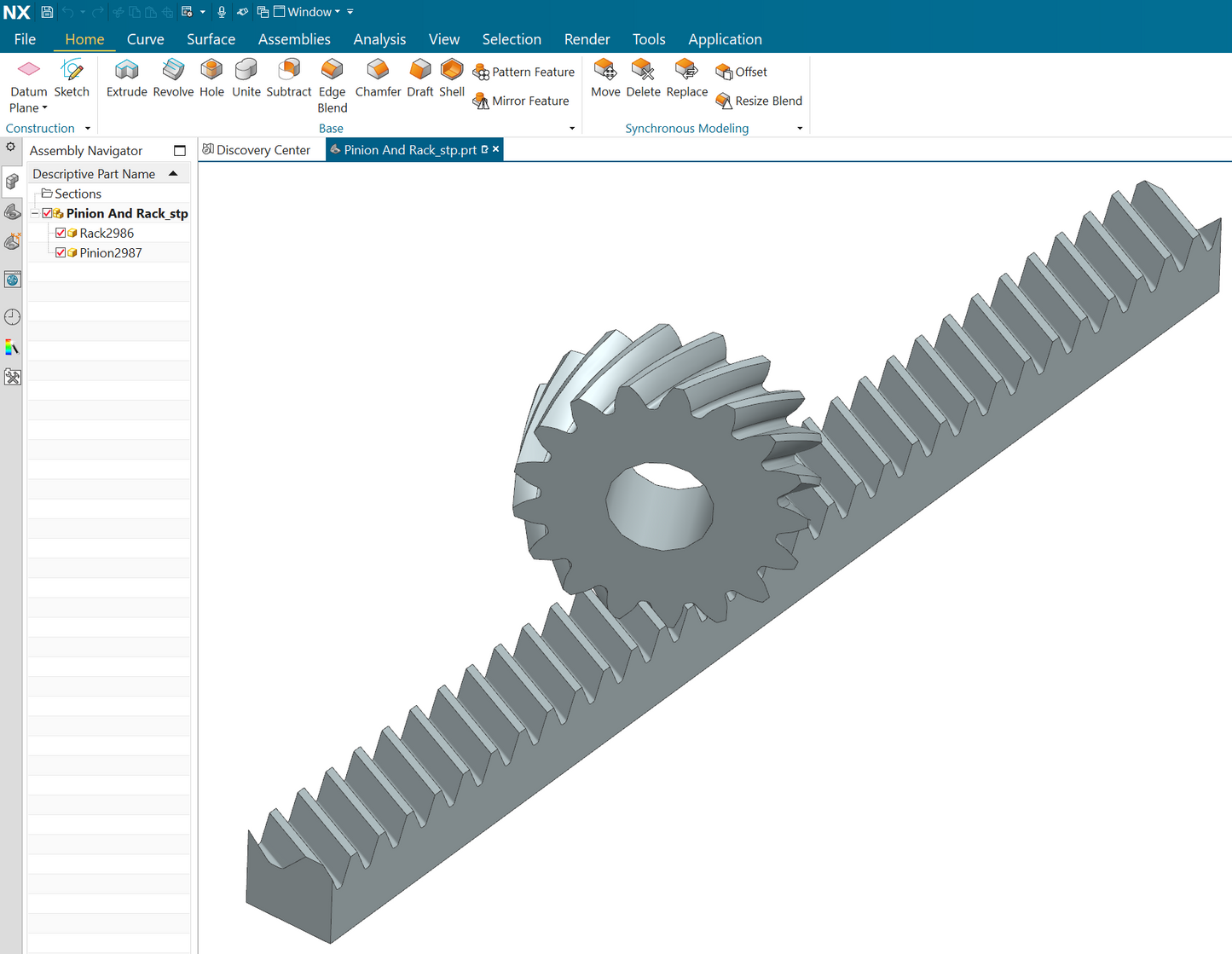

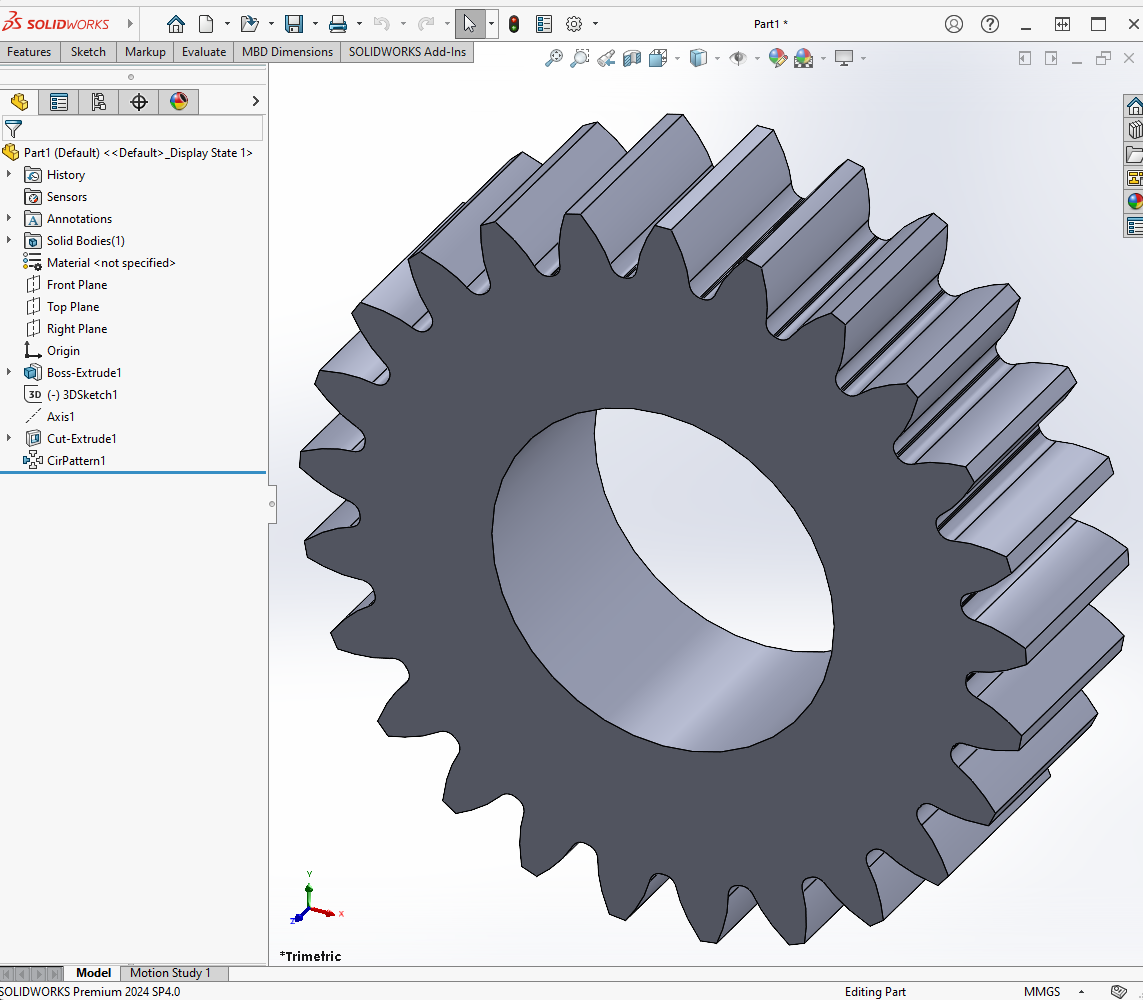

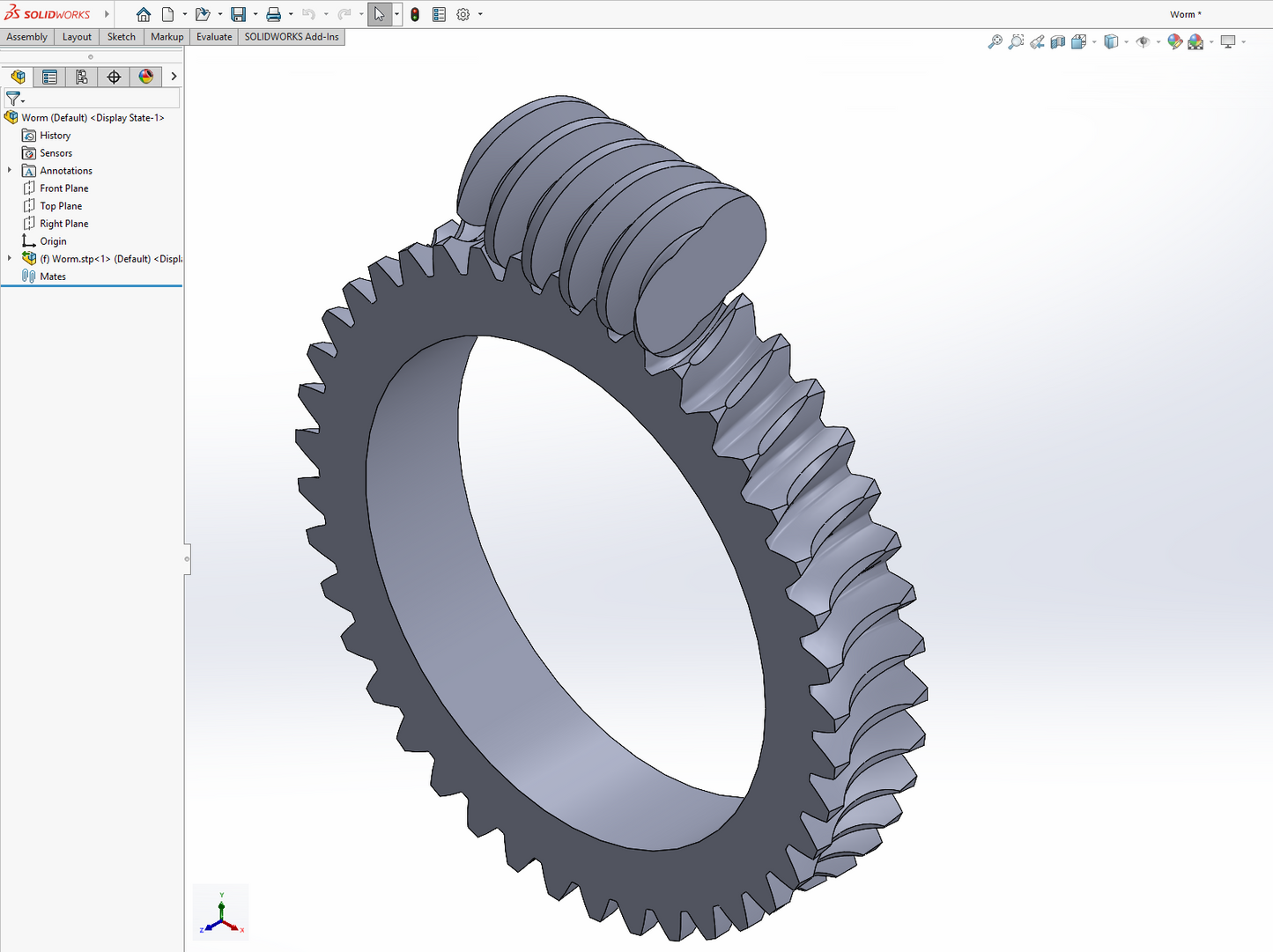

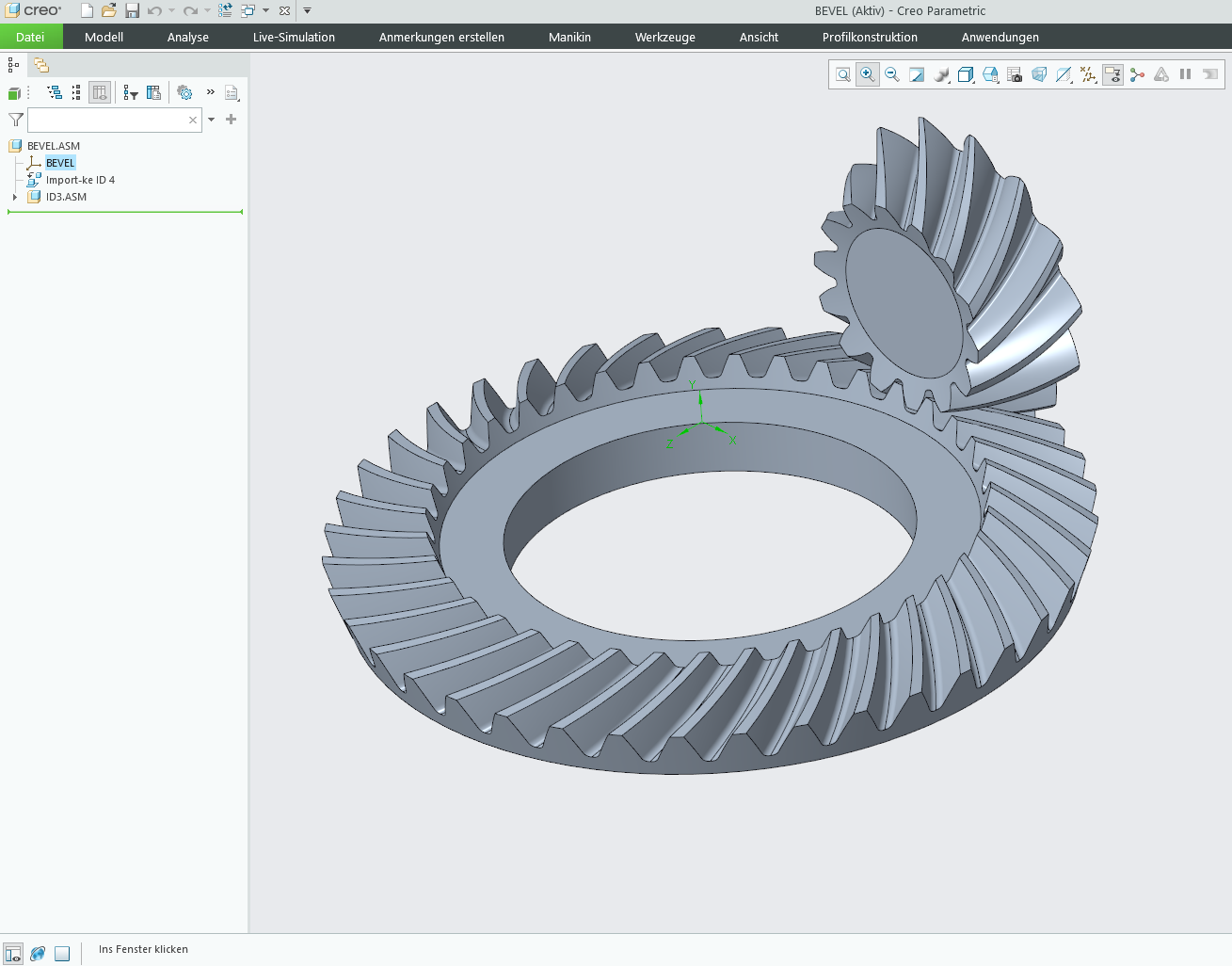

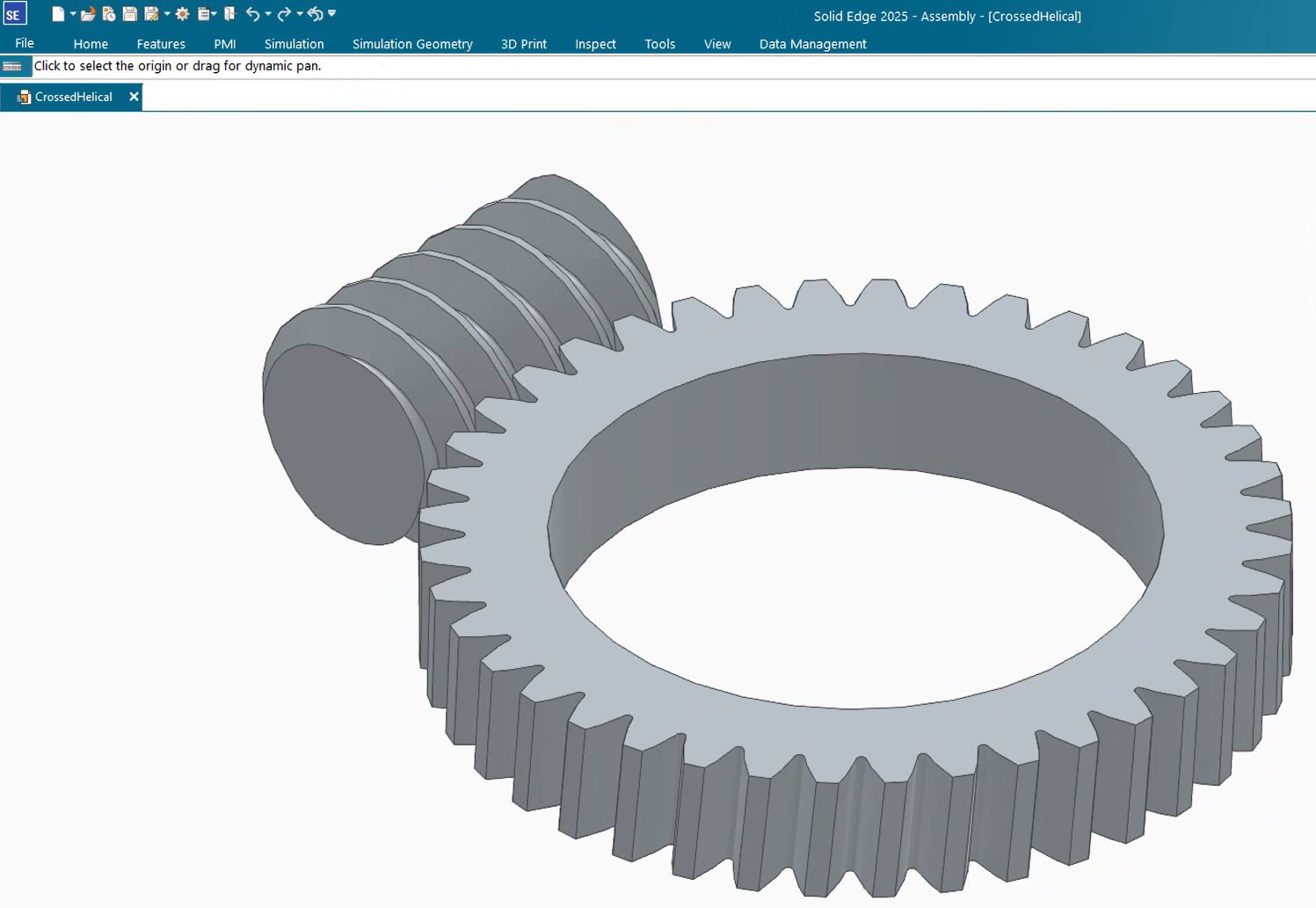

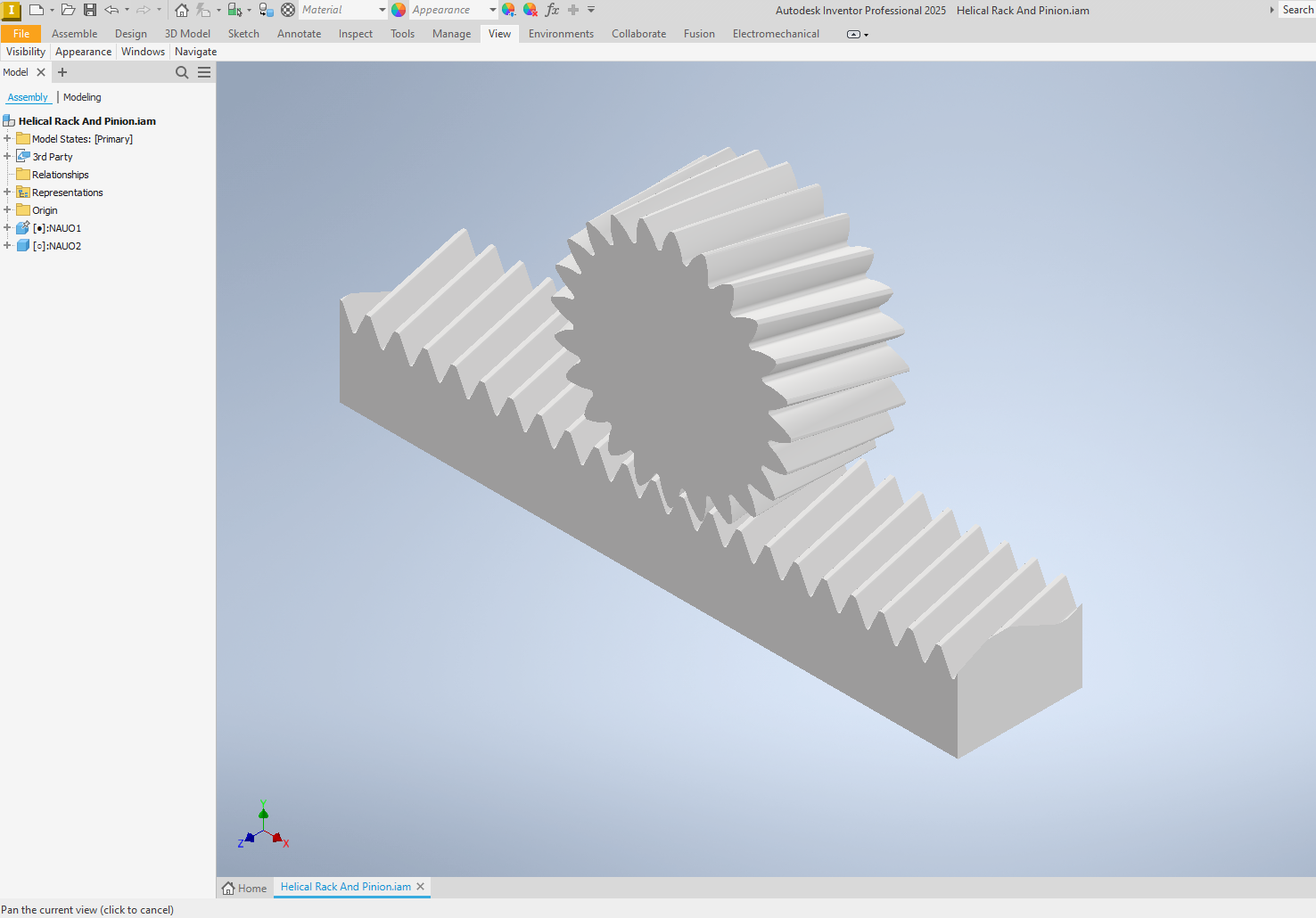

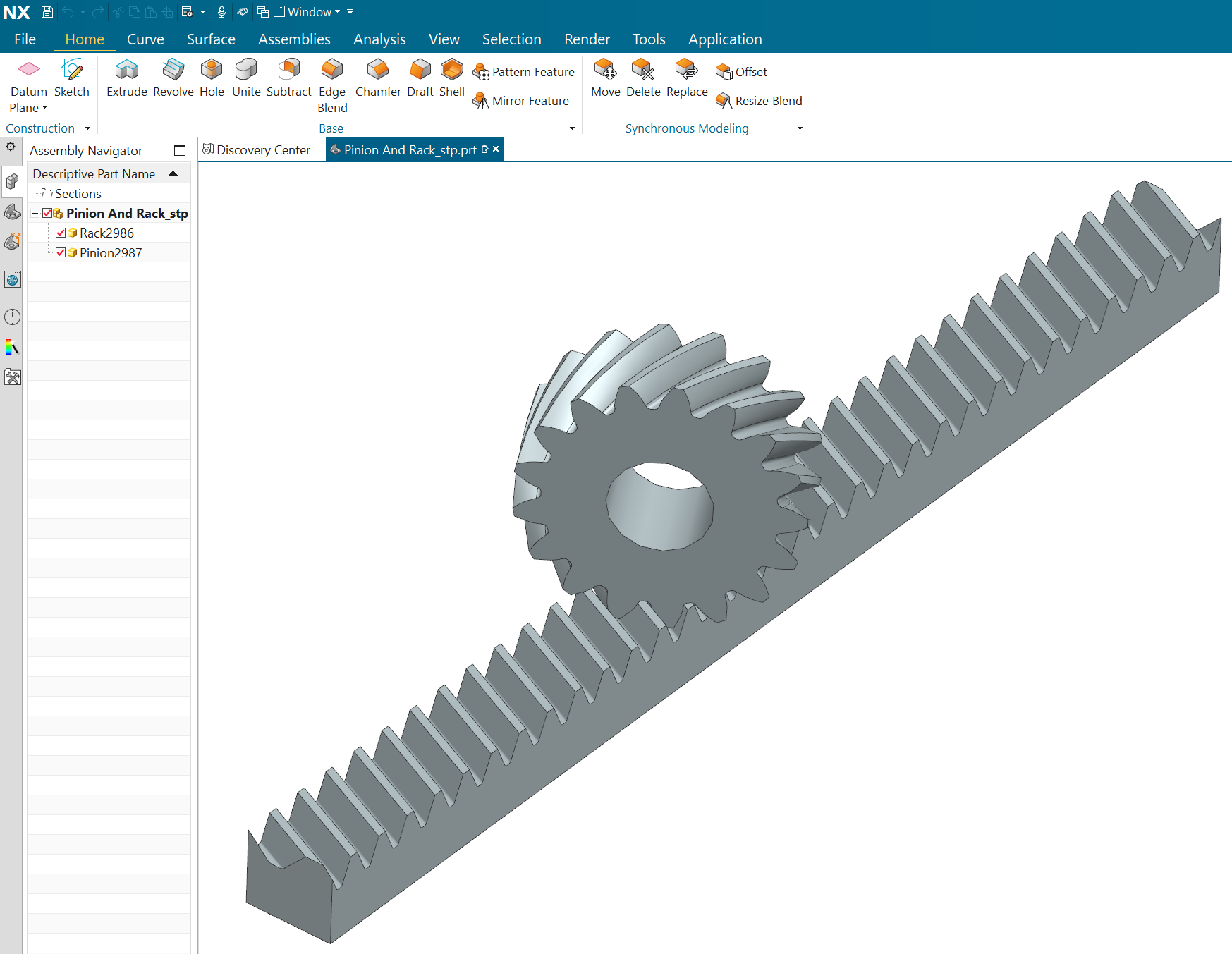

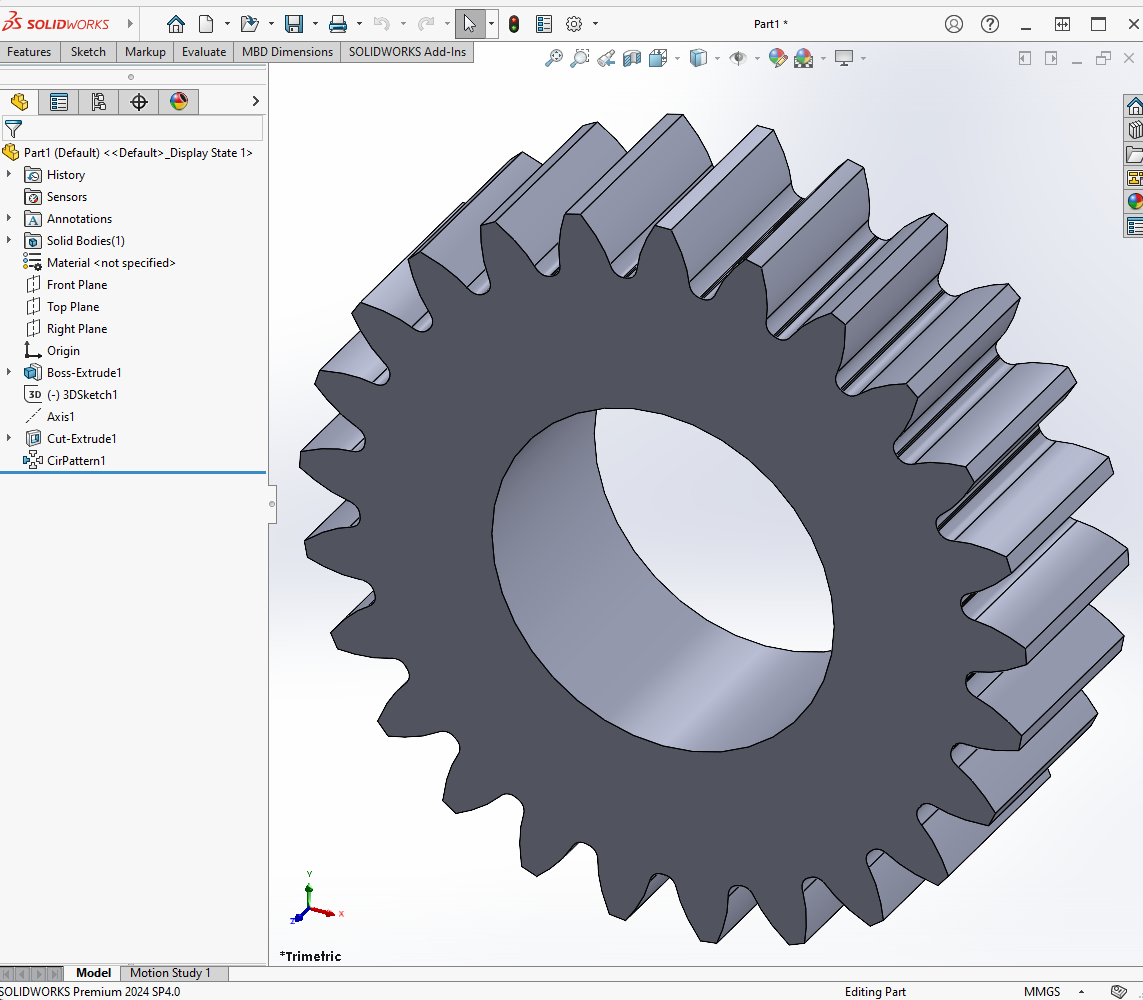

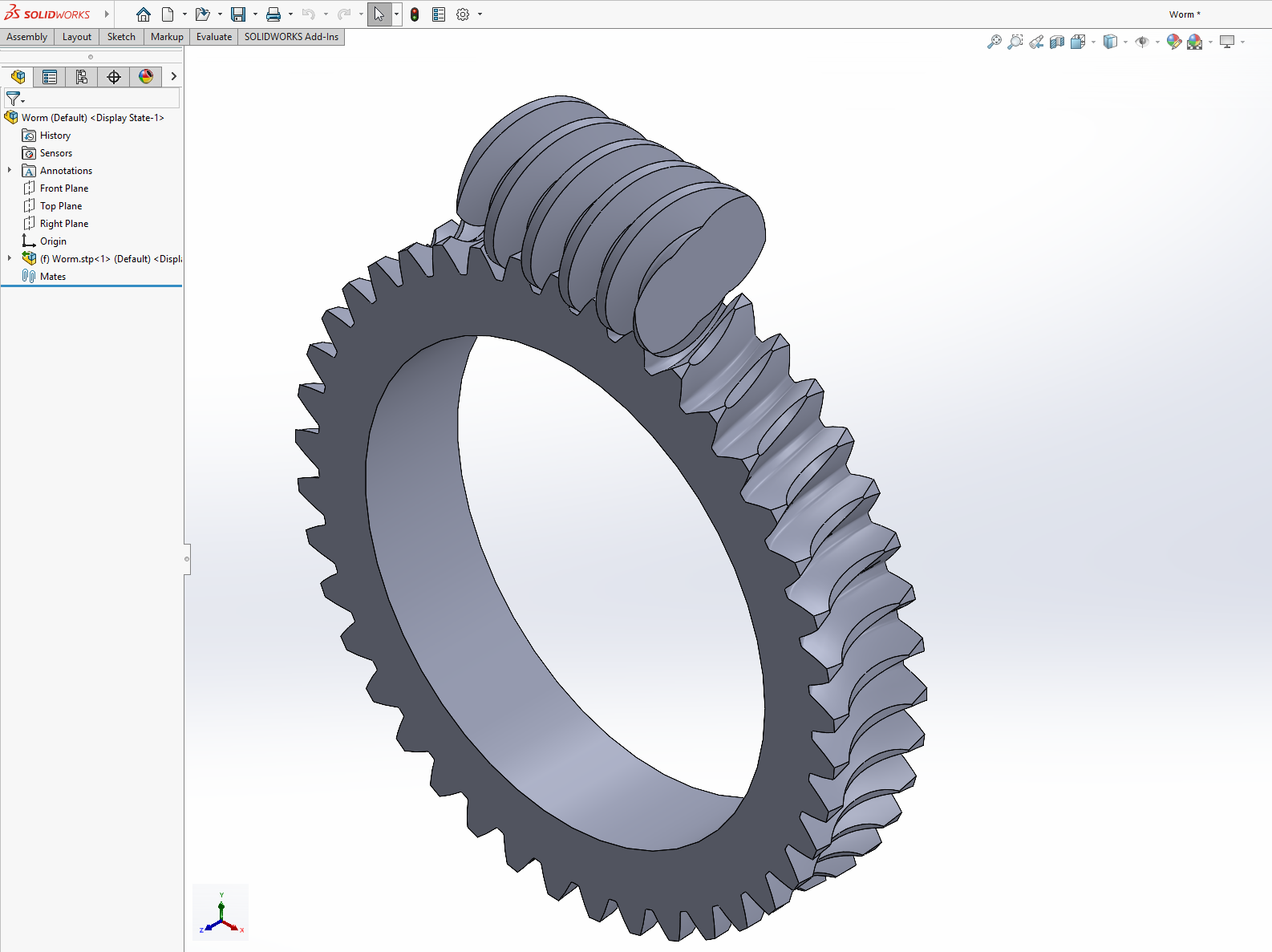

Display and export cylindrical gears with modifications, and straight and helical toothed bevel gears (apexes in one point, without modification), beveloid gear, splines (shaft-hub), shafts, racks

Display as skin model for checking paths of contact

Export shafts with force elements and rolling bearings

Rights: K05u, K05u1, K05u2

General Description

General Description

CAD interfaces

KISSsoft may include the below CAD interfaces to various systems. Thus, at the pressing of a button, the gears defined in KISSsoft can be exported to any of the below-mentioned CAD platforms. Gear Geometries supported are indicated above.

A gear can be generated for an existing construction or, simply, as a new part. Gears are generated by polylines, circular arc approximation or splines. The exact tooth profile is generated by manufacturing simulation considering tools like shaping cutter or protuberance hob. In addition, it is possible to place several gears on shafts already modelled in the CAD environment.

Neutral interfaces in 2D and 3D formats complete the CAD-specific export functions.

Export to CAM

KISSsoft includes a highly accurate detailed modeler for 3D gear geometries. Based on the geometry generated in KISSsoft, mold cavities, electrodes or final parts may be machined using 5-axis CNC machines.

For most gears, the 3D models can be generated including a protuberance to facilitate a roughing and a final machining operating. 3D models include gear modifications like lead, profile or topological modifications including chamfers or tip rounding.

Gears or cavities successfully machined by our customers include:

- Spur, helical and herringbone gears

- Spur, helical and spiral bevel gears

- Bevel gears with constant or varying tooth height

- Spur and helical face gears

- Worm gears (different shapes)

Geometries may be imported into any CAM software. Imported geometry includes profile and lead modifications, root geometry simulated from manufacturing, inner diameter, tip chamfer or rounding. Geometry resolution is finer than 0.1um.

Tests have confirmed that contact patterns of e.g., spiral bevel gears are matching with predictions calculated in KISSsoft.

Request specific information and technical papers on the subject from your local authorized reseller.

Gear geometry measurement may be controlled using KISSsoft measuring data (flank and root coordinates on measurement grid) and point normal vectors exported in different formats (e.g., to suit Gleason, Klingelnberg or Wenzel gear testers).

Share