Cylindrical + Planetary gears

Cylindrical + Planetary gears

Module List P1 (Basic)

Module List P1 (Basic)

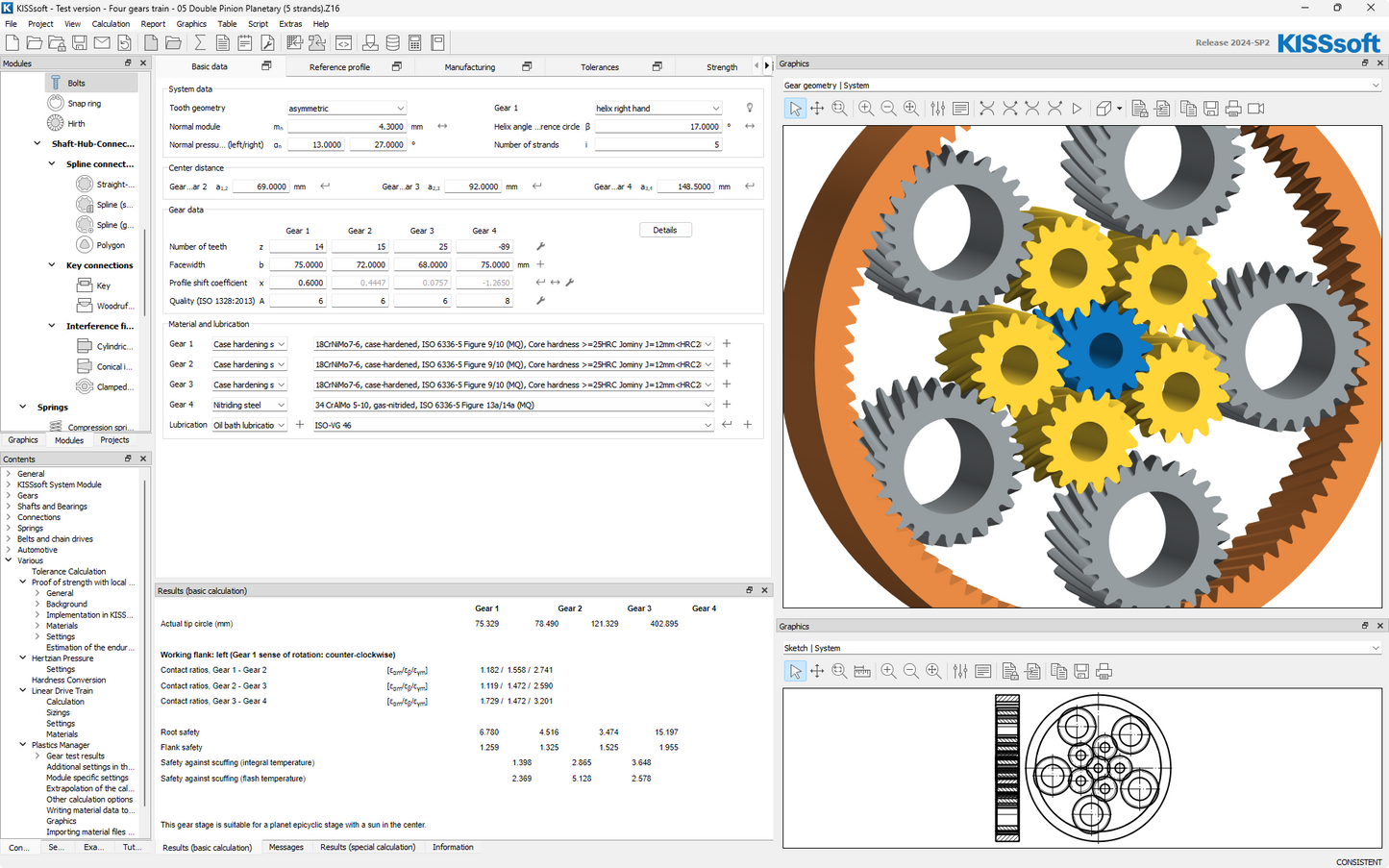

ZPK Cylindrical gears

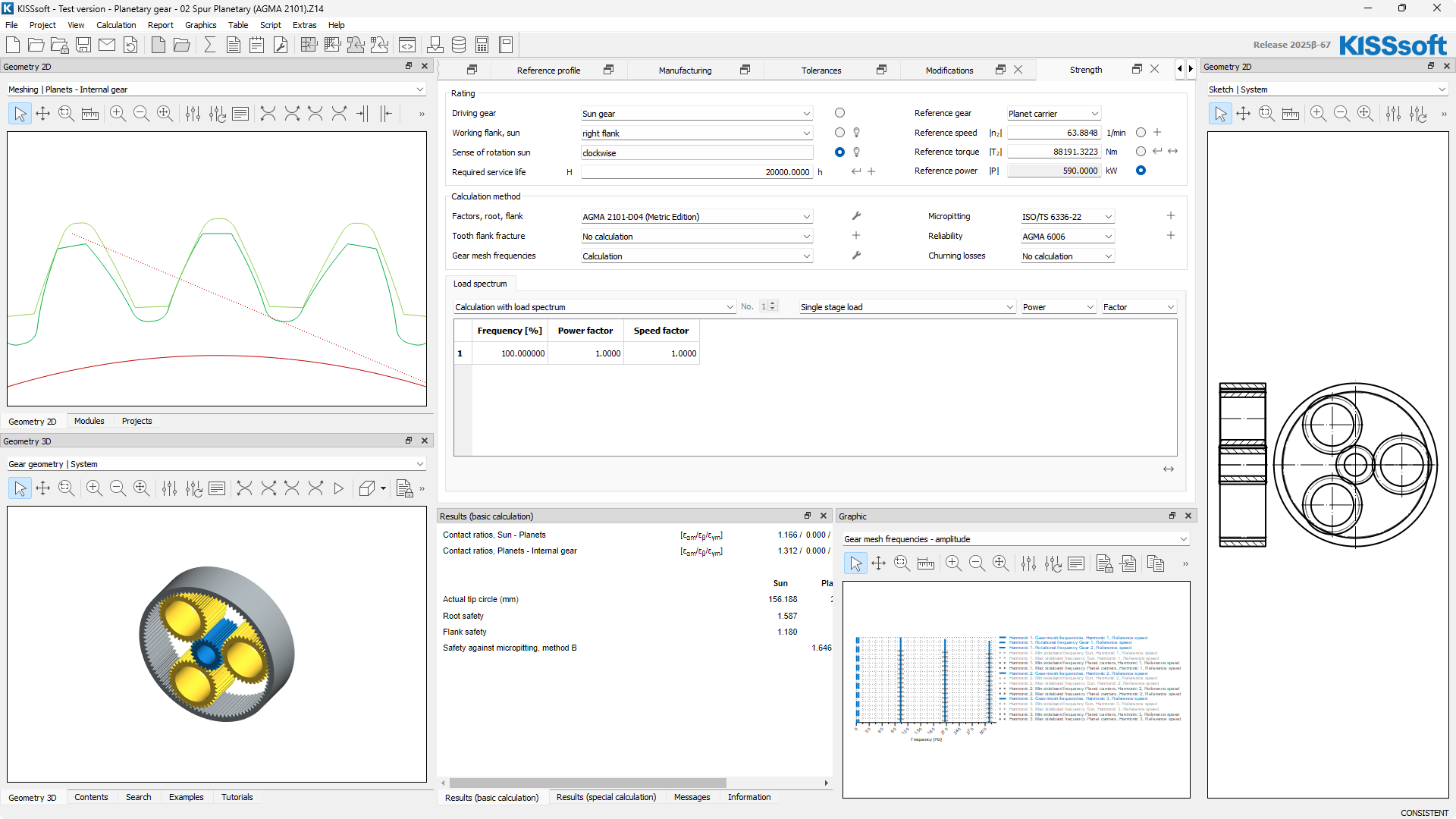

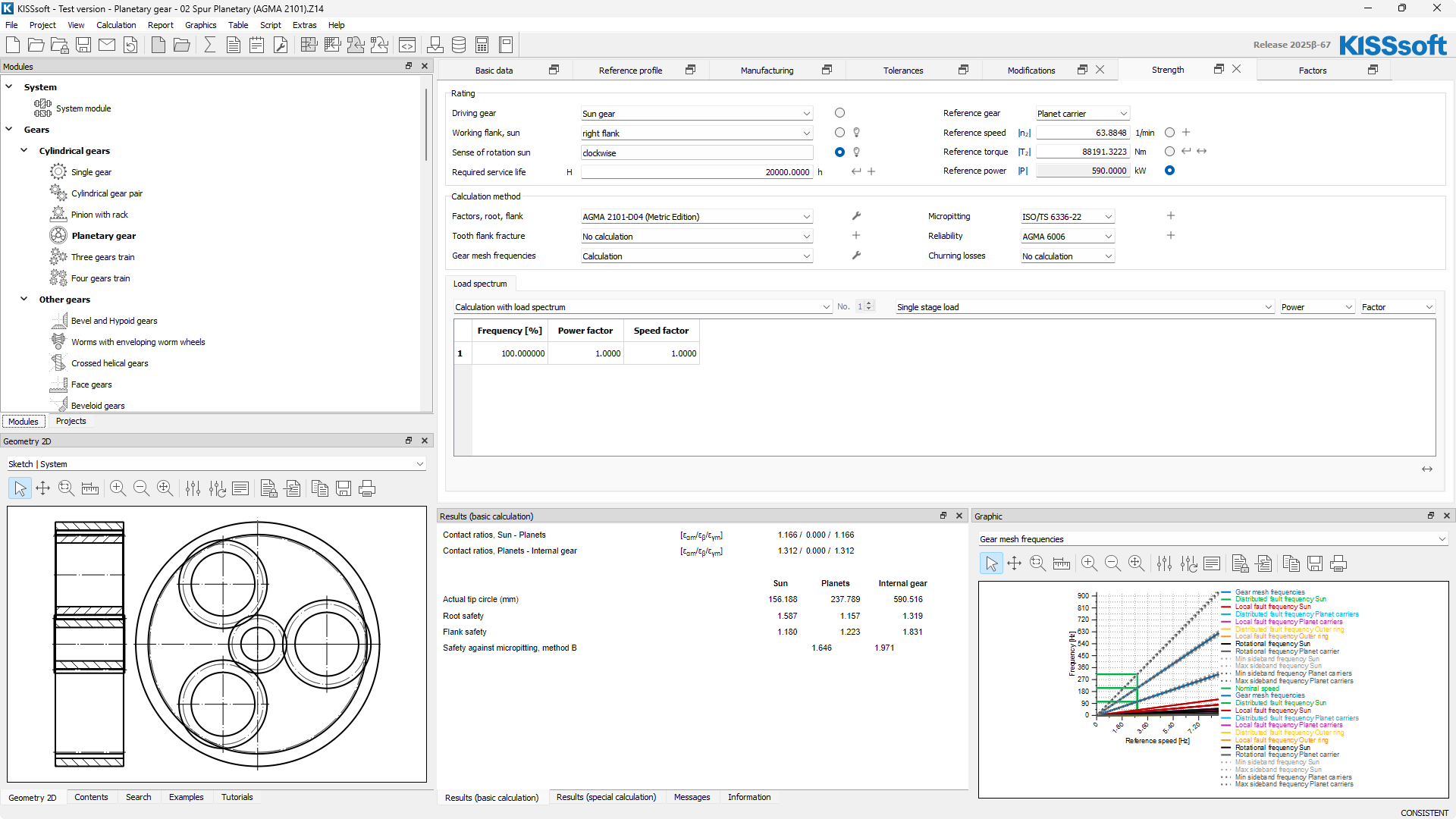

Calculation of cylindrical gear pairs and single gears

Calculation of geometry, control measurements (DIN 3960, DIN 3962, DIN 3963, DIN 58400)

Tolerances as specified in updated ISO 1328-1,2:2020

Reference profiles according to DIN 867, JIS 1701-1, deep tooth forms and short cut toothing, machining addition, grinding of tooth root

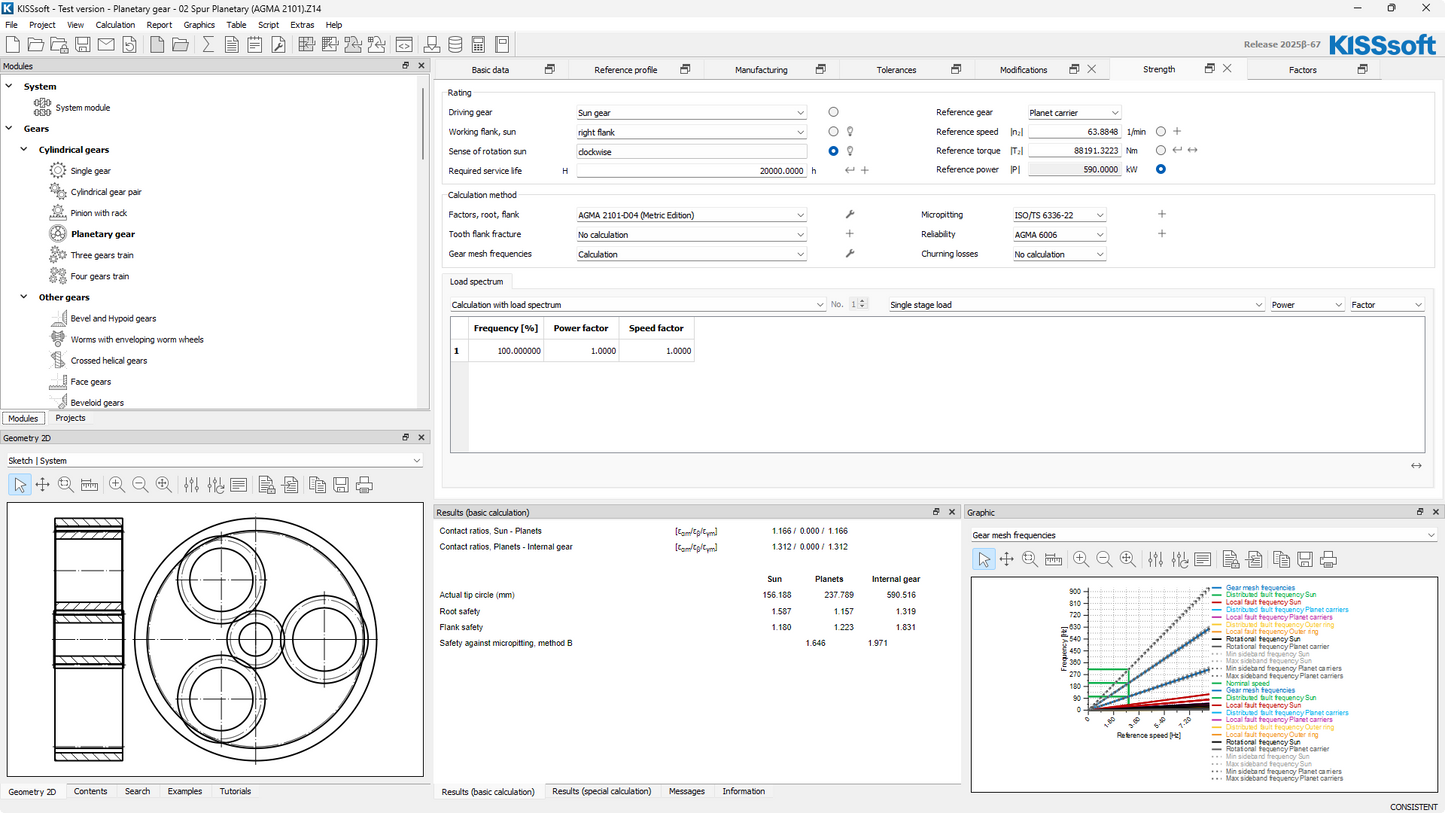

Strength calculation for a cylindrical gear, either as specified in ISO 6336 (module ZA10), DIN 3990 (module ZA11), AGMA 2001 (module ZA12), VDI 2545 (module ZA17), VDI 2736 (module ZA21) or GOST 21354-87 (module ZA22)

Input of speed for epicyclic gears configuration

Calculation of tooth friction and power loss according to Niemann

Flash temperature progression

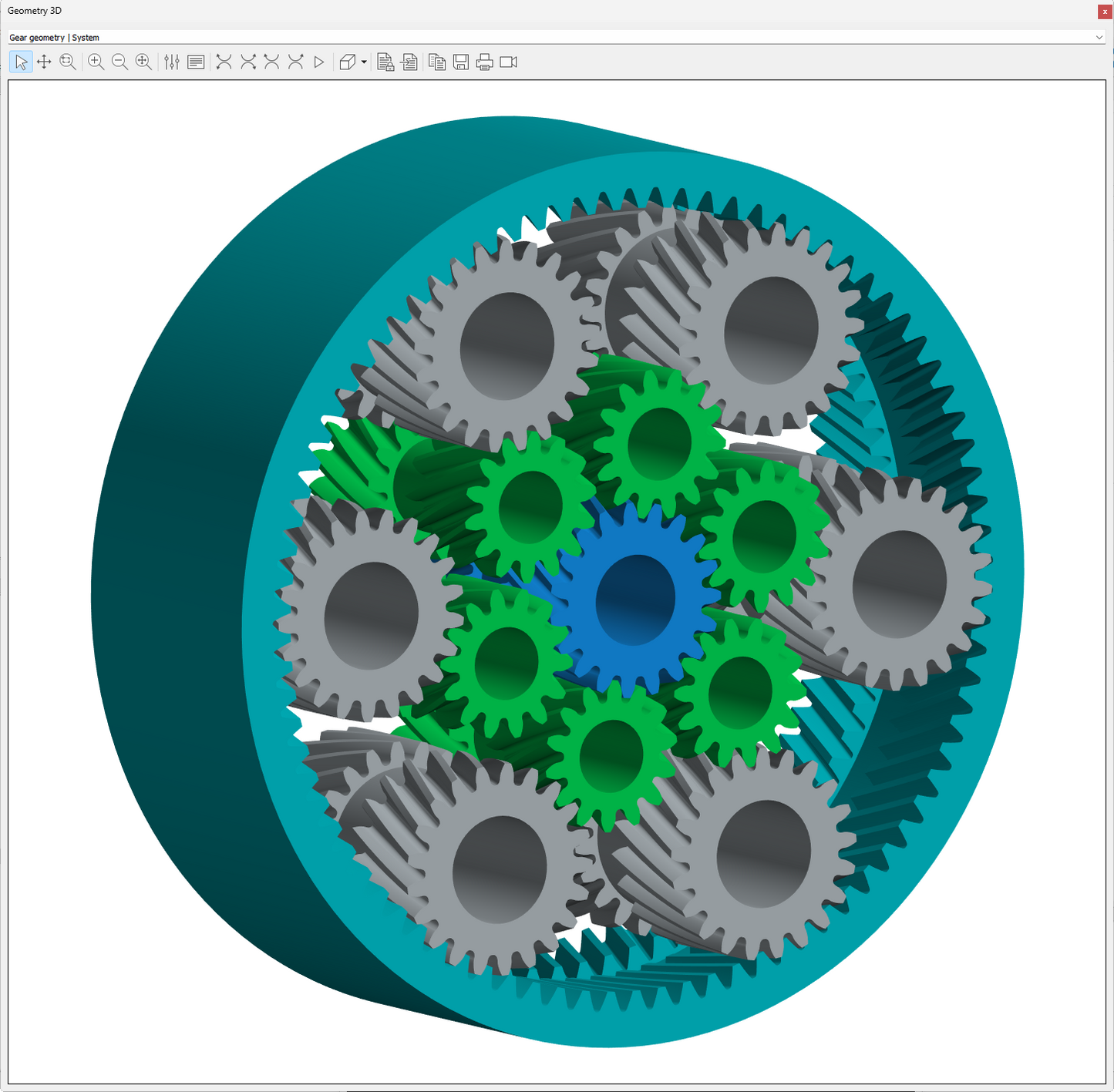

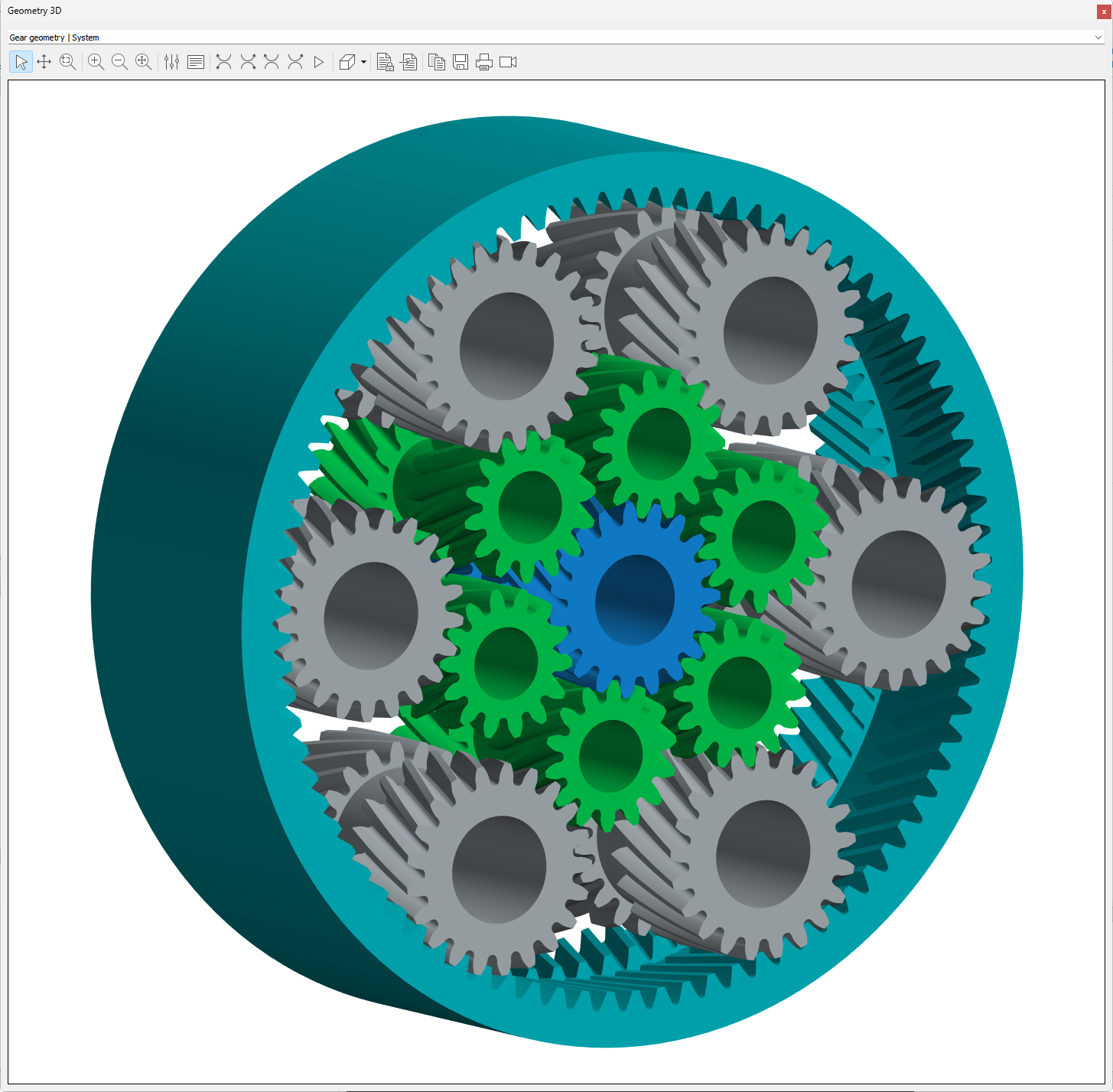

Calculation and 2D and 3D display of the tooth form for external and internal toothing

Scuffing according to DIN 3990 and ISO/TS 6336-20/21

Micropitting according to ISO/TS 6336-22 (Method B)

Calculation of case hardening depth according to FVA 271

Calculation of gear mesh frequencies, assembly phase frequencies and hunting tooth frequencies

Input of individual flank line modifications per tooth

Generation of variants for modifications

Arc of circle and spline approximation for 2D Export (requires module CA1)

Extended 2D and 3D display of the tooth form (module ZY1)

Tip shortening for involute or imported tooth forms

Animation of meshing gears, simultaneous display of more than one machining step, measuring function in the graphic, function for saving data for A – B comparison,

collision check, marking of contact point, marking of collision

Manual input of active tip and active root circles in the single gear calculation

Output of manufacturing drawings

Extensive material database

Save tools to the database and compare with existing tools

Contains this module: ZY1

Rights: Z01, Z01z, Z04b, Z04c, Z05i, Z05t, Z05v, Z19e, Z19m

ZA10 Strength according to ISO 6336:2019 and ISO 6336:2006 (replaced)

Rights: Z02a

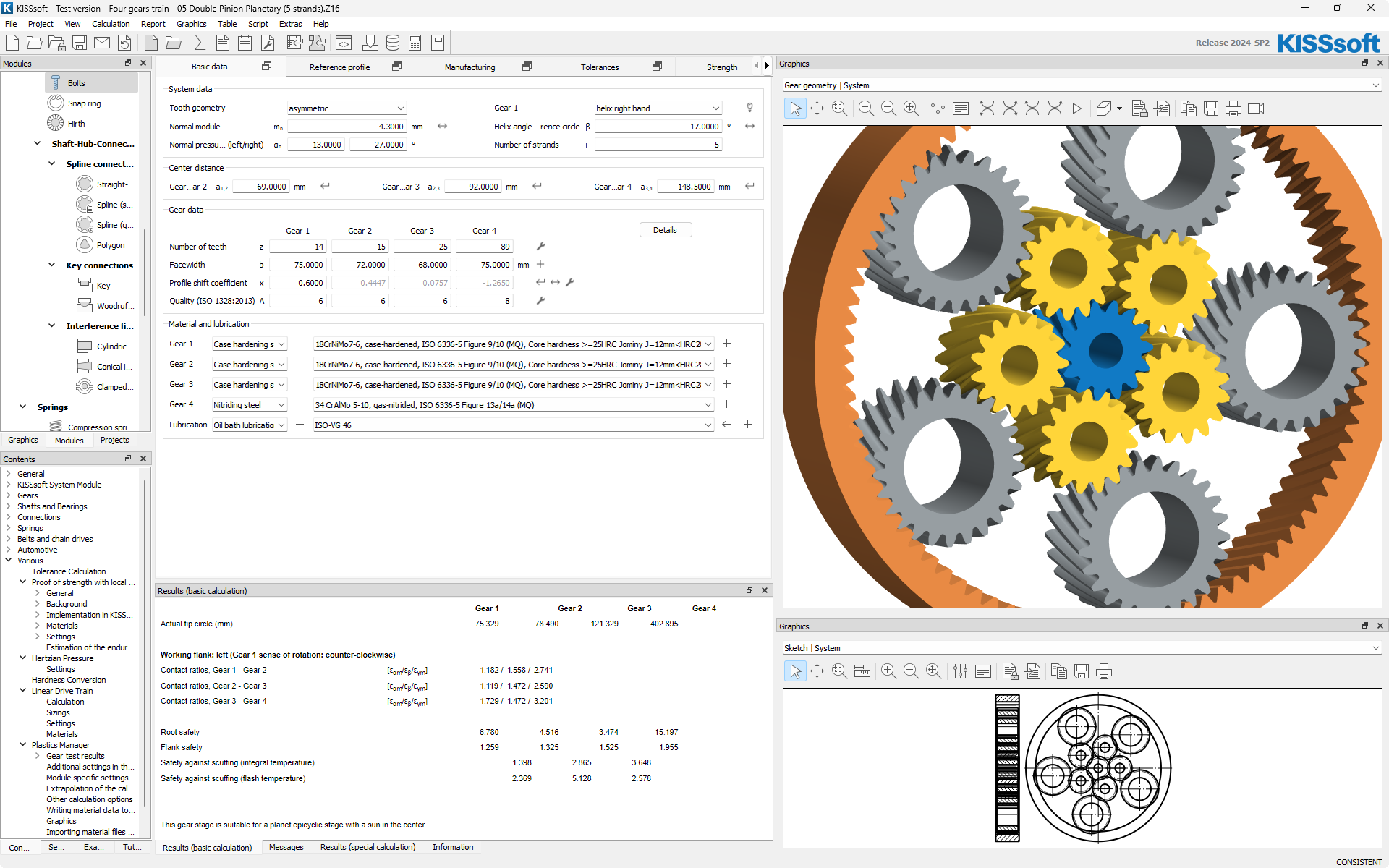

ZA1 Planetary gears, three gears, four gears

Rights: Z01a, Z19g

ZY1 Extended tooth form display

For 2D and 3D graphics, animation of meshing gears, simultaneous display of more than one machining step, measuring function in the graphic, function for saving data for A – B comparison, tooth form and tool in normal section, collision check, marking of contact point, marking of collision

Rights: Z05x, Z05j, Z05k

ZA5 Sizing functions and special calculations

Sizing of profile shift using different criteria

Calculation of profile shift and tooth thickness allowance taken from measured tooth geometry, pre-machining tools with grinding stock, topping tools

Sizing of the reference profile for a required transverse contact ratio

Rough sizing of modifications (microgeometry), tip and root relief (linear, progressive and logarithmical), crowning and helix angle modification sizing, taking into account axis inclinations as specified in ISO 6336-1, Annex B or in ISO 6336-1, Annex E (requires module ZA35)

Report for tolerances according to ISO 1328, DIN 3961, DIN 58405, BS 436, AGMA 2001 or AGMA 2015

Calculation with manufacturing profile shift

Sizing of center distance to take into account balanced specific sliding

Profile and flank line diagrams (K diagrams)

Rights: Z01x, Z15, Z19a, Z19d, Z19h, Z19l, Z19n

Module List P2 (Designer)

Module List P2 (Designer)

ZPK Cylindrical gears

Calculation of cylindrical gear pairs and single gears

Calculation of geometry, control measurements (DIN 3960, DIN 3962, DIN 3963, DIN 58400)

Tolerances as specified in updated ISO 1328-1,2:2020

Reference profiles according to DIN 867, JIS 1701-1, deep tooth forms and short cut toothing, machining addition, grinding of tooth root

Strength calculation for a cylindrical gear, either as specified in ISO 6336 (module ZA10), DIN 3990 (module ZA11), AGMA 2001 (module ZA12), VDI 2545 (module ZA17), VDI 2736 (module ZA21) or GOST 21354-87 (module ZA22)

Input of speed for epicyclic gears configuration

Calculation of tooth friction and power loss according to Niemann

Flash temperature progression

Calculation and 2D and 3D display of the tooth form for external and internal toothing

Scuffing according to DIN 3990 and ISO/TS 6336-20/21

Micropitting according to ISO/TS 6336-22 (Method B)

Calculation of case hardening depth according to FVA 271

Calculation of gear mesh frequencies, assembly phase frequencies and hunting tooth frequencies

Input of individual flank line modifications per tooth

Generation of variants for modifications

Arc of circle and spline approximation for 2D Export (requires module CA1)

Extended 2D and 3D display of the tooth form (module ZY1)

Tip shortening for involute or imported tooth forms

Animation of meshing gears, simultaneous display of more than one machining step, measuring function in the graphic, function for saving data for A – B comparison,

collision check, marking of contact point, marking of collision

Manual input of active tip and active root circles in the single gear calculation

Output of manufacturing drawings

Extensive material database

Save tools to the database and compare with existing tools

Contains this module: ZY1

Rights: Z01, Z01z, Z04b, Z04c, Z05i, Z05t, Z05v, Z19e, Z19m

ZA10 Strength according to ISO 6336:2019 and ISO 6336:2006 (replaced)

Rights: Z02a

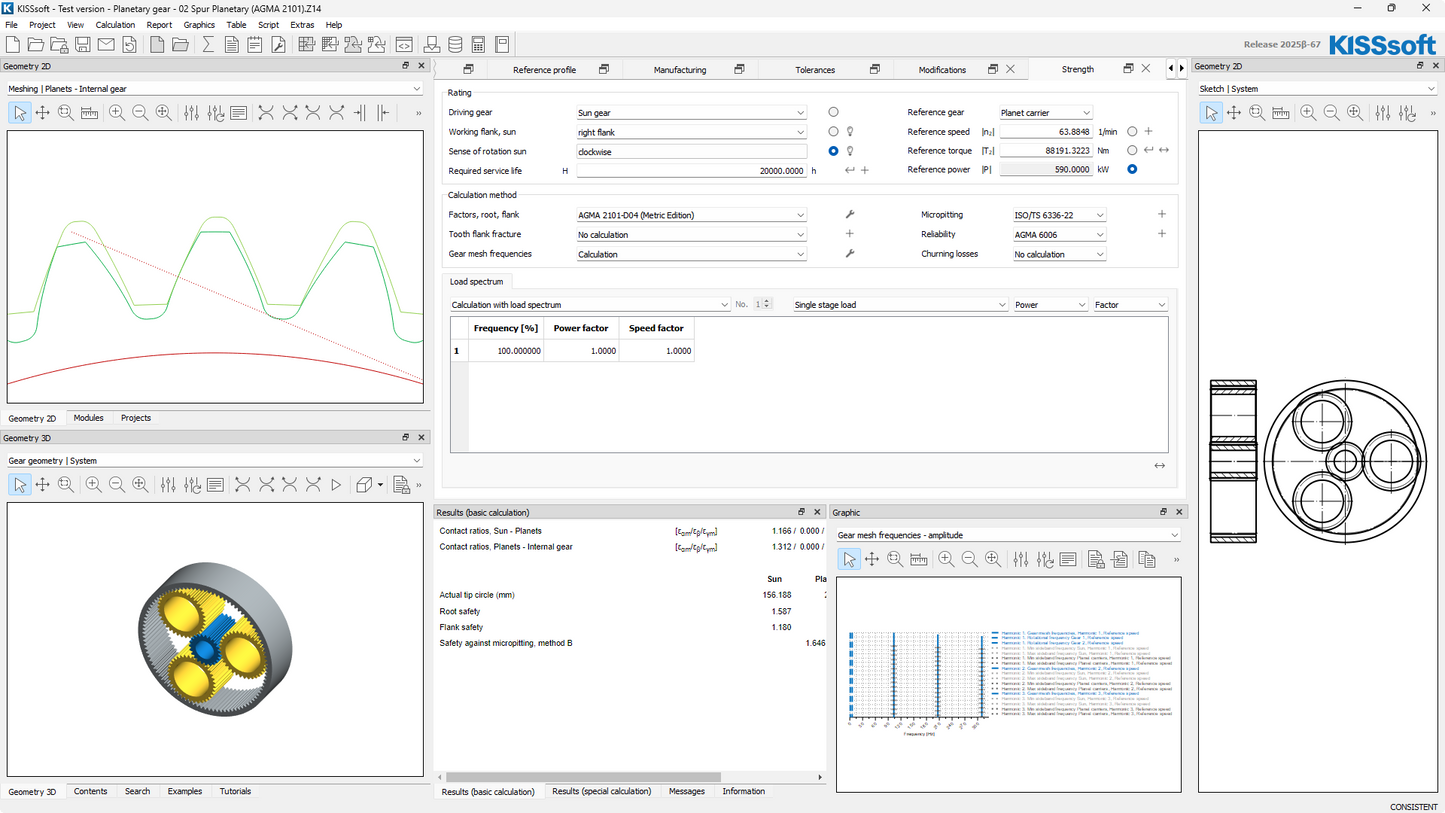

ZA1 Planetary gears, three gears, four gears

Rights: Z01a, Z19g

ZY1 Extended tooth form display

For 2D and 3D graphics, animation of meshing gears, simultaneous display of more than one machining step, measuring function in the graphic, function for saving data for A – B comparison, tooth form and tool in normal section, collision check, marking of contact point, marking of collision

Rights: Z05x, Z05j, Z05k

ZA5 Sizing functions and special calculations

Sizing of profile shift using different criteria

Calculation of profile shift and tooth thickness allowance taken from measured tooth geometry, pre-machining tools with grinding stock, topping tools

Sizing of the reference profile for a required transverse contact ratio

Rough sizing of modifications (microgeometry), tip and root relief (linear, progressive and logarithmical), crowning and helix angle modification sizing, taking into account axis inclinations as specified in ISO 6336-1, Annex B or in ISO 6336-1, Annex E (requires module ZA35)

Report for tolerances according to ISO 1328, DIN 3961, DIN 58405, BS 436, AGMA 2001 or AGMA 2015

Calculation with manufacturing profile shift

Sizing of center distance to take into account balanced specific sliding

Profile and flank line diagrams (K diagrams)

Rights: Z01x, Z15, Z19a, Z19d, Z19h, Z19l, Z19n

ZA3 Rough sizing macrogeometry

for gear pairs and planetary gear stages

Sizing according to required safeties, determination of the center distance and facewidth for solutions with the same torque capacity, display of multiple variants, specification of total weight

Rights: Z03

ZA4 Fine sizing macro geometry

for gear pairs and planetary gear stages, three gears, and four gears

Variation of the module, number of teeth, profile shifts, pressure angle, etc.

Calculation of all executable variants, taking into account the installation constraints of planet gears

Automatic sizing of deep tooth forms (requires module ZA5)

Calculation of transmission error for all variants (requires module ZA30)

Specification of cutter and pinion-type cutter lists per gear

All solutions are classified on the basis of different criteria

Display of results in tables and graphics

Rights: Z04, Z04a

ZZ1 Load spectra and transmittable torque

Calculation of transmittable power with and without load spectrum

Calculation of service life with and without load spectrum

Calculation of safeties with load spectrum (for cylindrical, bevel, and cross helical gears)

Taking into account the direction of rotation of the individual stages, and their load direction (for cylindrical gears)

Graphical display of speed and torque classes

Rights: Z16, Z16a, Z18, Z18a, K23

Module List P3 (Expert)

Module List P3 (Expert)

ZPK Cylindrical gears

Calculation of cylindrical gear pairs and single gears

Calculation of geometry, control measurements (DIN 3960, DIN 3962, DIN 3963, DIN 58400)

Tolerances as specified in updated ISO 1328-1,2:2020

Reference profiles according to DIN 867, JIS 1701-1, deep tooth forms and short cut toothing, machining addition, grinding of tooth root

Strength calculation for a cylindrical gear, either as specified in ISO 6336 (module ZA10), DIN 3990 (module ZA11), AGMA 2001 (module ZA12), VDI 2545 (module ZA17), VDI 2736 (module ZA21) or GOST 21354-87 (module ZA22)

Input of speed for epicyclic gears configuration

Calculation of tooth friction and power loss according to Niemann

Flash temperature progression

Calculation and 2D and 3D display of the tooth form for external and internal toothing

Scuffing according to DIN 3990 and ISO/TS 6336-20/21

Micropitting according to ISO/TS 6336-22 (Method B)

Calculation of case hardening depth according to FVA 271

Calculation of gear mesh frequencies, assembly phase frequencies and hunting tooth frequencies

Input of individual flank line modifications per tooth

Generation of variants for modifications

Arc of circle and spline approximation for 2D Export (requires module CA1)

Extended 2D and 3D display of the tooth form (module ZY1)

Tip shortening for involute or imported tooth forms

Animation of meshing gears, simultaneous display of more than one machining step, measuring function in the graphic, function for saving data for A – B comparison,

collision check, marking of contact point, marking of collision

Manual input of active tip and active root circles in the single gear calculation

Output of manufacturing drawings

Extensive material database

Save tools to the database and compare with existing tools

Contains this module: ZY1

Rights: Z01, Z01z, Z04b, Z04c, Z05i, Z05t, Z05v, Z19e, Z19m

ZA10 Strength according to ISO 6336:2019 and ISO 6336:2006 (replaced)

Rights: Z02a

ZA1 Planetary gears, three gears, four gears

Rights: Z01a, Z19g

ZY1 Extended tooth form display

For 2D and 3D graphics, animation of meshing gears, simultaneous display of more than one machining step, measuring function in the graphic, function for saving data for A – B comparison, tooth form and tool in normal section, collision check, marking of contact point, marking of collision

Rights: Z05x, Z05j, Z05k

ZA5 Sizing functions and special calculations

Sizing of profile shift using different criteria

Calculation of profile shift and tooth thickness allowance taken from measured tooth geometry, pre-machining tools with grinding stock, topping tools

Sizing of the reference profile for a required transverse contact ratio

Rough sizing of modifications (microgeometry), tip and root relief (linear, progressive and logarithmical), crowning and helix angle modification sizing, taking into account axis inclinations as specified in ISO 6336-1, Annex B or in ISO 6336-1, Annex E (requires module ZA35)

Report for tolerances according to ISO 1328, DIN 3961, DIN 58405, BS 436, AGMA 2001 or AGMA 2015

Calculation with manufacturing profile shift

Sizing of center distance to take into account balanced specific sliding

Profile and flank line diagrams (K diagrams)

Rights: Z01x, Z15, Z19a, Z19d, Z19h, Z19l, Z19n

ZA3 Rough sizing macrogeometry

for gear pairs and planetary gear stages

Sizing according to required safeties, determination of the center distance and facewidth for solutions with the same torque capacity, display of multiple variants, specification of total weight

Rights: Z03

ZA4 Fine sizing macro geometry

for gear pairs and planetary gear stages, three gears, and four gears

Variation of the module, number of teeth, profile shifts, pressure angle, etc.

Calculation of all executable variants, taking into account the installation constraints of planet gears

Automatic sizing of deep tooth forms (requires module ZA5)

Calculation of transmission error for all variants (requires module ZA30)

Specification of cutter and pinion-type cutter lists per gear

All solutions are classified on the basis of different criteria

Display of results in tables and graphics

Rights: Z04, Z04a

ZZ1 Load spectra and transmittable torque

Calculation of transmittable power with and without load spectrum

Calculation of service life with and without load spectrum

Calculation of safeties with load spectrum (for cylindrical, bevel, and cross helical gears)

Taking into account the direction of rotation of the individual stages, and their load direction (for cylindrical gears)

Graphical display of speed and torque classes

Rights: Z16, Z16a, Z18, Z18a, K23

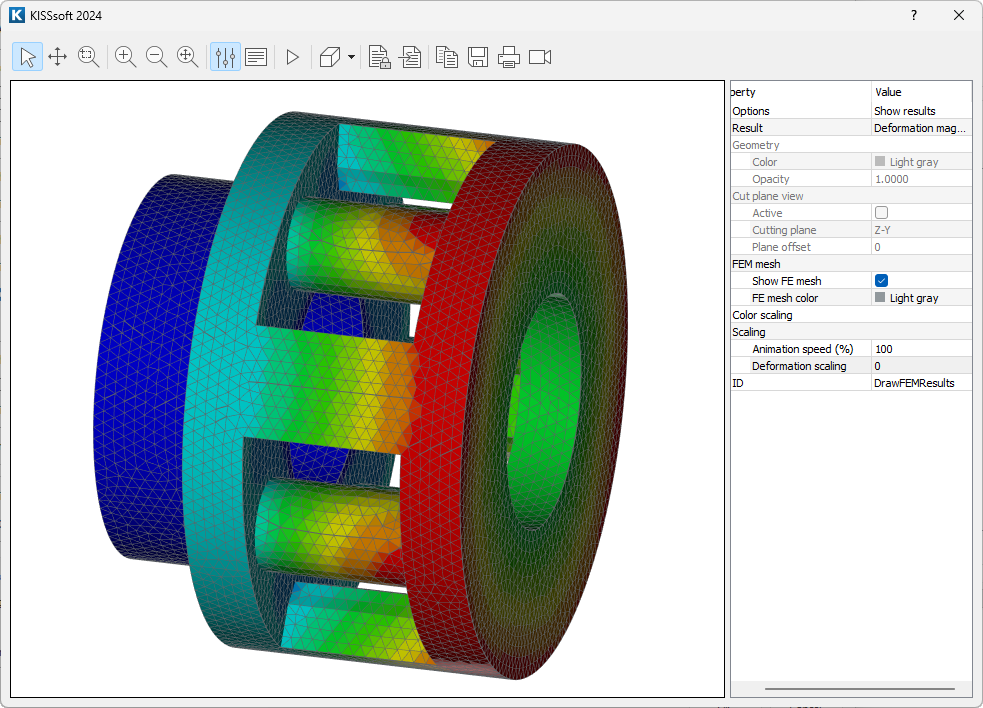

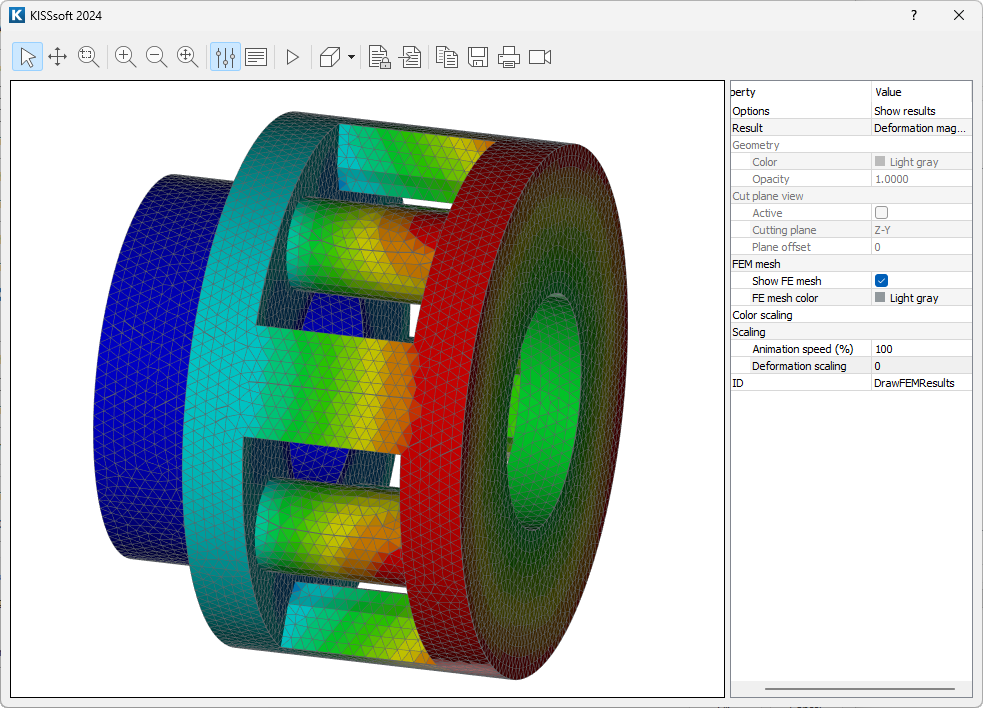

ZA24 Tooth root stresses with 2D FEM

Calculation of tooth root stresses for cylindrical gear pairs (with straight or helical teeth)

Calculation with integrated FEM Solver CM2®

FEM results displayed in KISSsoft

Rights: Z38a

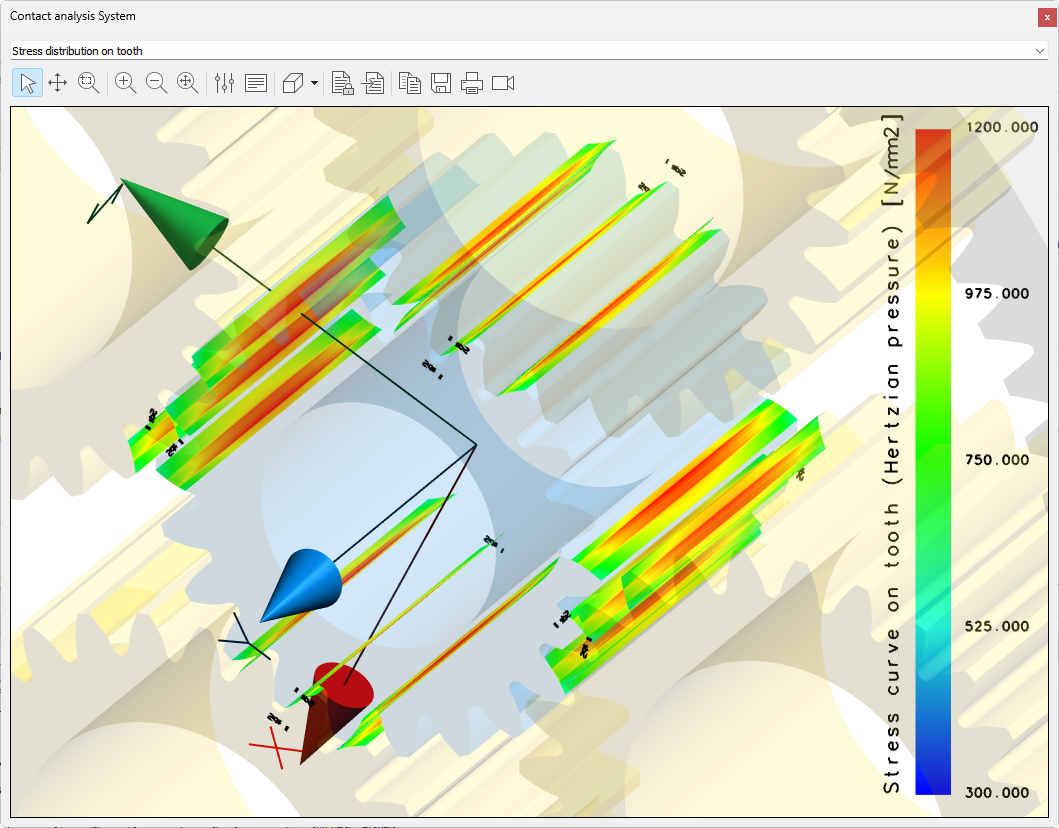

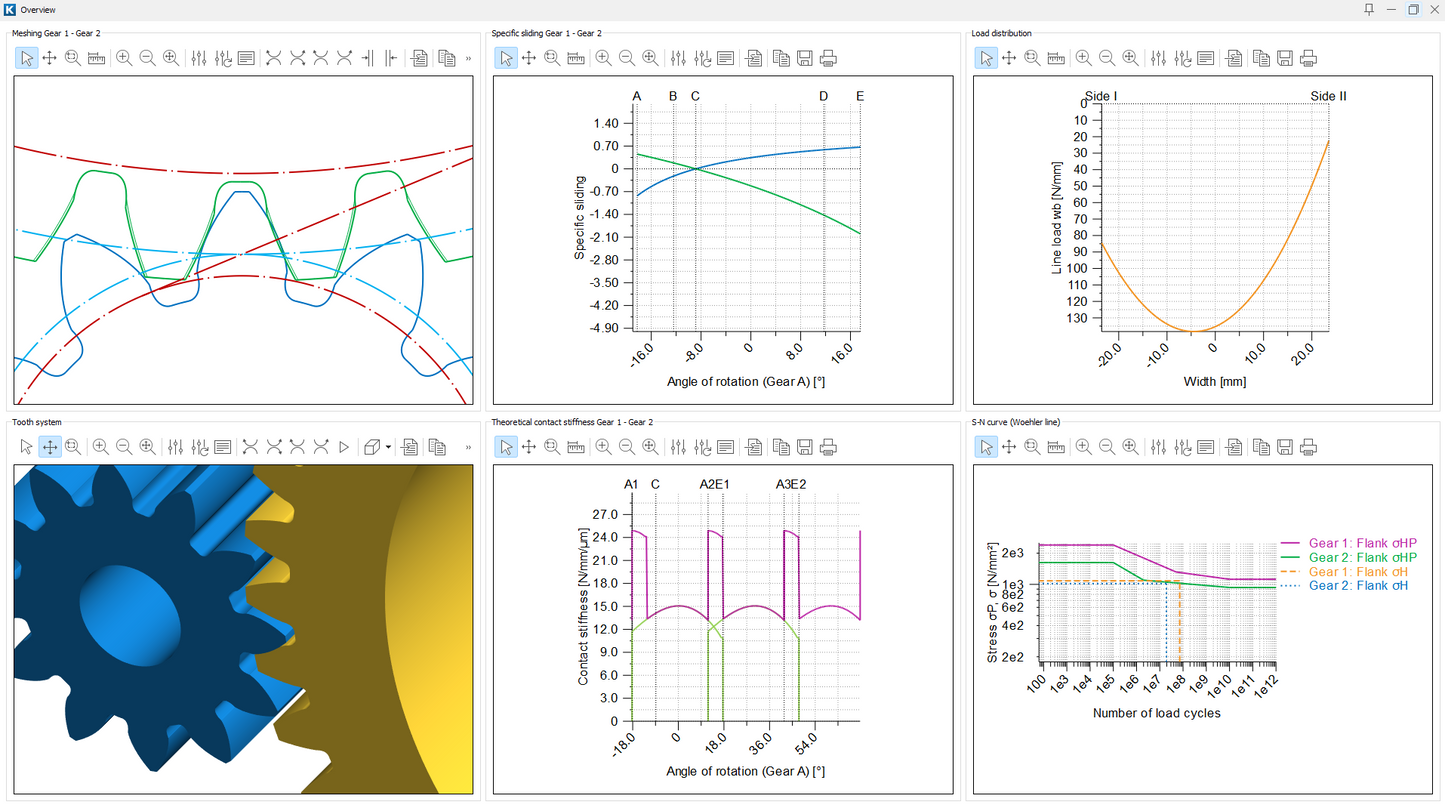

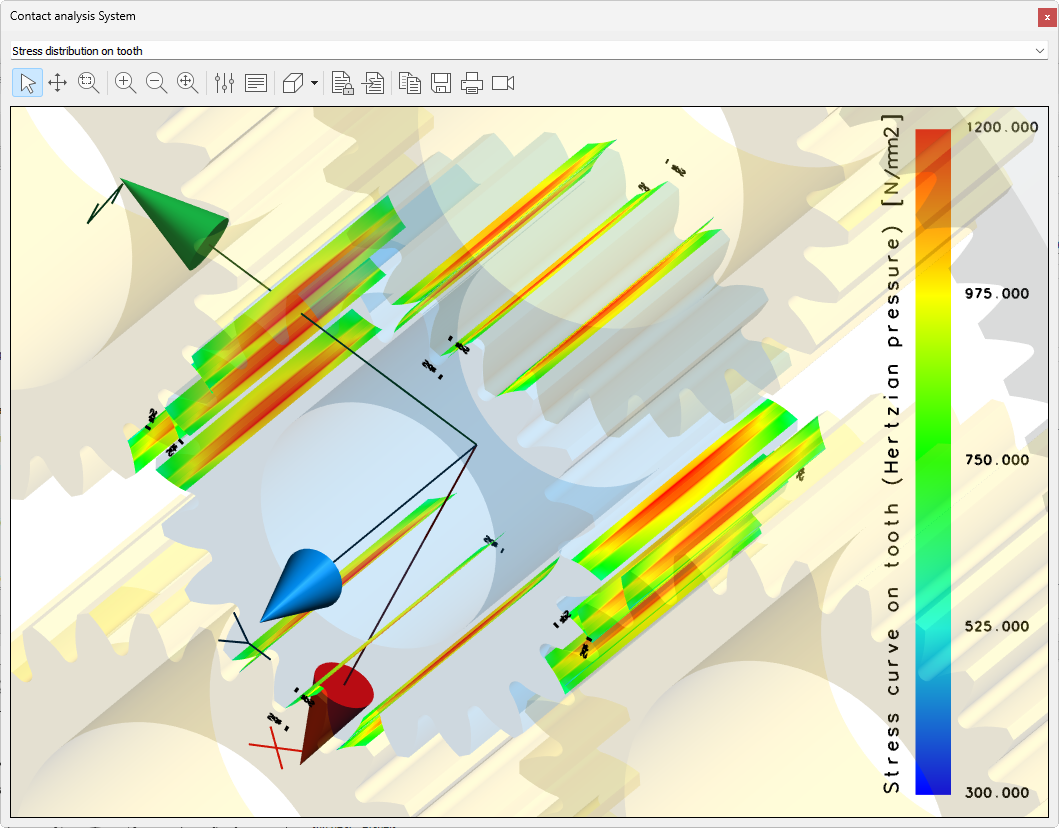

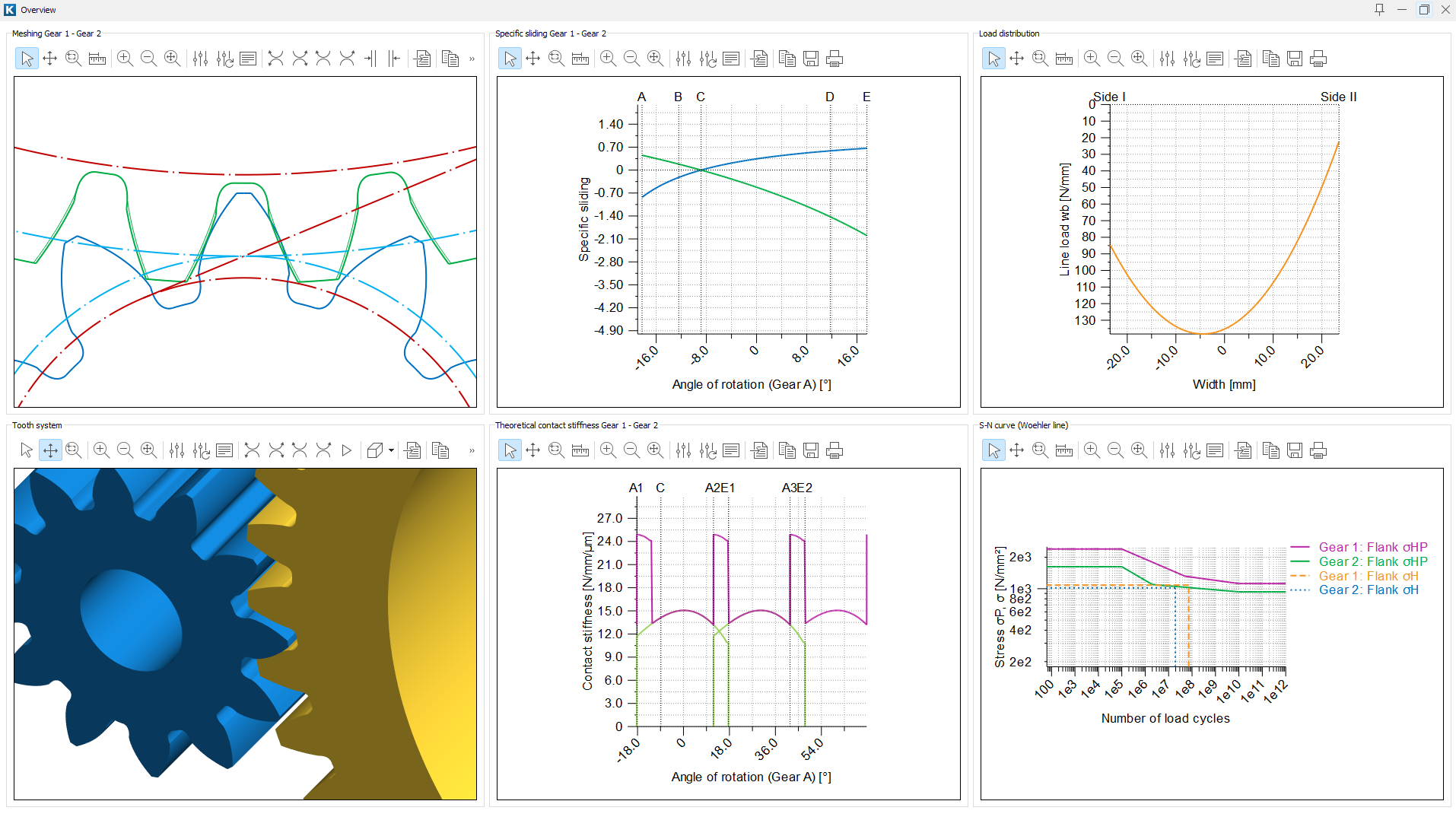

ZA30 Contact analysis for cylindrical gears

taking into account flank modifications and shaft deformation

Tooth flank fracture according to ISO/TS 6336-4:2019 (requires module ZZ4)

Calculation of the excitation force according to FVA-No. 487

Calculation of path of contact under load

Graphical display of the results in the excitation force, efficiency, forces and stresses groups

Calculation and display of Hertzian pressure, contact pattern and tooth root stresses along the actual tooth flank

Load-free contact pattern and display of the assembly contact pattern

Calculation with conical profile shift

Calculation of contact stiffness and transmission error under load, based on the actual tooth form

Display of specific sliding, sliding velocity and sliding factors for gears under load from actual tooth form

Display of friction power and local heat generation along the meshing

Wear calculation for plastic (dry run) and steel (cold wear)

Calculation and display of the progression of wear

Calculation of safety against micropitting according to ISO/TS 6336-22

Calculation of lubrication gap according to ISO/TS 6336-22 and AGMA 925 with actual normal force

Calculation of power loss and speed across the meshing

Rights: Z24, Z25, Z27, Z30, Z31, Z31a, Z32, Z32b, Z32c, Z36, Z39a, Z39b, Z39c, Z39d and K05w

ZA35 Face load factor KHbeta according to ISO 6336-1, Appendix E

Calculation of gaping and load distribution while taking into account flank modifications and shaft deformation

Tolerance variations with (+/-)fma and (+/-)fhb

Results are displayed in graphics and reports

Results for individual planets can be output

Rights: Z02c

ZZ4 Tooth flank fracture for cylindrical and bevel gears

For cylindrical gears according to ISO/TS 6336-4

For bevel and hypoid gears according to ISO/DTS 10300-4:2019 (draft) (requires modules ZC2 or ZC9)

Rights: Z07k

ZA34 Planetary stage contact analysis

taking into account flank modifications and shaft deformation

Floating sun wheel

All other functionalities as described in ZA30

Rights: Z24, Z25, Z27, Z30, Z31, Z31a, Z32c, Z34, Z36, Z39a, Z39b, Z39c, Z39d, K05w

General Description

General Description

Planetary gears

Overview

- Based on helical gear calculation modules

- Calculation of planet pin location for non-evenly spaced planets

- Influence of rim thickness of ring gear and planet gears considered

- Assembly check

- Sizing function for load distribution factor along AGMA 6123

- Rough and fine sizing function

Strength rating, planets

- DIN 3990 method B, DIN 3990 method B with YF along method C, DIN 3990 Part 41 (vehicles)

- ISO 6336:2006 and ISO 6336:2019

- Static rating against yield

- AGMA 2001-C95, AGMA 2101-D04, AGMA 2001-D04

- AGMA 6004-F88, AGMA 6011-J14, API 613 :2021, AGMA 6014-B15, AGMA 6015-A13, GOST 21354-87

- Plastic gears along Niemann, VDI 2545, VDI 2545 modified, VDI2736

- BV / Rina FREMM3.1, Rina 2010, DNV41.2, Loyds Register 2013

- ISO 13691:2001 (high speed gears)

- For nominal load or load spectrum

- Planet system reliability

- Micropitting rating along ISO/TS 6336-22, scuffing rating along ISO 6336-20, ISO 6336-21, DIN 3990, AGMA 925

- Flank fracture rating along ISO/TS 6336-4 and case crushing rating along DNV 41.2

Kg calculation

- For systems with perfect pin position or for pins with positioning error

- Quasi-static load distribution neglecting dynamic effects

- Sun may be floating or stationary

- Kg is calculated for momentary force equilibrium for different meshing positions

- Considering system equilibrium for in-phase and out-of-phase systems

- Phasing check

Planetary tooth contact analysis

FEM calculation of planetary carrier

- Planetary carrier torsion is calculated inside KISSsoft with FEM

- Salome / Code Aster is used as pre-processor and solver, using Python scripts

- Based on parameterized model of the carrier (import of carrier geometry is not directly possible)

- Mesh generation is automatic

- Includes sizing function for planetary carrier geometry

- Results may also be directly imported from FEM results file

Ring gear deformation

- In case of ring gears supported only on one side, the conical deformation may be considered for the planet – ring gear mesh

Sun gear arrangement

- Floating or fixed sun gear

- In case of floating sun gear, quasistatic momentary equilibrium is calculated

Link to shaft calculations

- Planetary carrier tilting in carrier bearings or due to manufacturing errors may be considered from shaft calculation

- Sun shaft twist, sun shaft tilting may be considered in LTCA with planets

- Planet pin deformation and planet bearing deformations is automatically imported from shaft calculation

- Planetary tooth contact analysis may be integrated into System Module models

Share